Revitalizing South Africa’s Sugar Industry: The Promise of Biomethanol and Multi-Product Biorefineries

South Africa’s sugar industry is vital to its rural economy and provides many jobs. For many years, it has generated great value, with sugarcane cultivation and sugar production supporting the lives of over a million people. However, a series of challenges, such as low-cost, subsidized imports, the domestic sugar tax, and climate change, have put the sector in a tough spot. The old way of just producing sugar is no longer viable. To address these issues, researchers are exploring the integration of biorefineries that convert sugarcane and its by-products into a range of value-added products, including biomethanol, bioethanol, chemicals, and electricity.

This is not merely an economic issue; it is a social one. The decline of the sugar industry threatens the stability of entire rural towns in KwaZulu-Natal and Mpumalanga, South africa. As the number of sugarcane farmers has plummeted by 60% and jobs have decreased by an estimated 45% over the past two decades, the need for a radical shift has become undeniable (van der Merwe, 2024).

The solution lies not in abandoning the industry, but in a revolutionary transformation: embracing a multi-product biorefinery model (Areeya et al., 2024). This approach goes beyond sugar. It uses the entire sugarcane plant to create a variety of valuable products, including an important renewable fuel: biomethanol. learn also about this south african official site about sugar cane prospective.

The Historical Context: From Prosperity to Precarity

The South African sugar industry has a rich history. The first commercial sugar shipment from Durban occurred in 1850. By 1975, domestic consumption exceeded one million tons. The industry then evolved into a global cost-competitive producer. It served as a major colonial activity that shaped the economy. In the post-apartheid era, it became an important force for land reform and socio-economic development. Since 1994, 21% of freehold land used for cane has been transferred to Black owners.

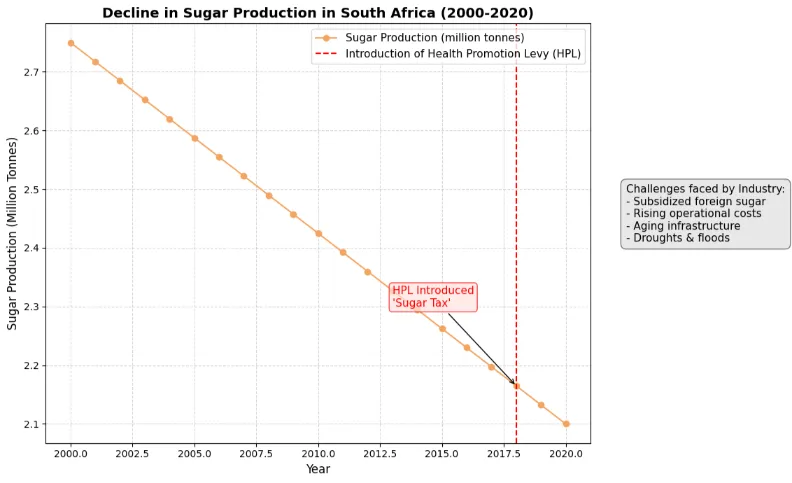

However, the industry’s resilience has been tested by a series of shocks. The introduction of the Health Promotion Levy (HPL), or “sugar tax,” in 2018 was a major blow, leading to a substantial decline in local demand. At the same time, the influx of heavily subsidized foreign sugar sold at prices lower than production costs has made it hard for local farmers to compete. These challenges, along with increasing operational costs, aging infrastructure, and the severe effects of droughts and floods, have created an unsustainable environment. The annual sugar production in South Africa has declined by nearly 25% over the last 20 years, from 2.75 million to 2.1 million tonnes per annum, forcing the industry to export surplus sugar at a loss (Formann et al., 2020).

The Biorefinery Revolution: A New Blueprint for Sustainability

The traditional sugar mill’s primary product is crystalline sugar, while by-products like molasses and bagasse are often underutilized. Bagasse, the fibrous residue of the sugarcane stalk, is typically burned in low-efficiency boilers to generate steam and power the mill. Molasses, a syrup-like by-product, is used in animal feed or fermented into small quantities of industrial ethanol.

A multi-product biorefinery fundamentally changes this approach. It sees the sugarcane plant as a versatile resource, a “green crude oil,” able to produce not just sugar but also a variety of valuable products. This range of products is essential for finding new revenue sources, stabilizing the industry, and building a more resilient and sustainable value chain.

The South African Sugarcane Value Chain Master Plan to 2030 is a joint effort between the government and industry. It clearly acknowledges the need for diversification. The plan points out opportunities for new products, including:

- Bioethanol for fuel blending: Offering a cleaner alternative to traditional petrol.

- Sustainable Aviation Fuel (SAF): A high-value product with significant potential in the global decarbonization of the aviation sector.

- Bioplastics and biochemicals: Such as polylactic acid (PLA) and succinic acid, which can replace petroleum-based materials.

- Electricity cogeneration: Utilizing the high energy content of bagasse to generate and export surplus electricity to the national grid.

Biomethanol: The Game-Changer

Among these diversification options, biomethanol is a particularly promising pathway for the South African sugar industry. Methanol is a key ingredient for thousands of chemical products and is becoming a popular fuel source for shipping and other industries aiming to reduce carbon emissions. Made from the thermochemical conversion of biomass like bagasse, biomethanol presents a real, large-scale opportunity.

Biorefinery Pathways and Products

- Multi-Product Biorefineries: Various scenarios have been modeled for converting sugarcane residues (bagasse and trash) into products such as methanol, ethanol, lactic acid, furfural, butanol, and electricity. Methanol synthesis and ethanol-lactic acid co-production showed strong economic returns, with methanol production also offering the best environmental performance due to low reagent use Petersen, A., Louw, J., & Görgens, J. (2024).

- Value Addition from Molasses: Single-stage crystallization processes produce A-molasses, which can be converted into high-value products like succinic acid and fructooligosaccharides. Co-production of these products can yield high internal rates of return (up to 56.1%), supporting economic sustainability and job creation Dogbe, E., Mandegari, M., & Görgens, J. (2020).

Here’s why biomethanol is a perfect fit:

- Resource Abundance: South Africa processes an average of 19 million tons of sugarcane and 8 million tons of bagasse each year. This provides a consistent and abundant supply of feedstock for biomethanol production.

- Environmental Benefits: Biogenic methanol from sugarcane offers significant greenhouse gas (GHG) emission reductions compared to fossil fuel-based methanol, contributing to South Africa’s climate change goals.

- Market Demand: The global demand for green methanol is accelerating, driven by the maritime industry’s need for sustainable fuels. A local production facility could serve both domestic and international markets, creating a new export commodity.

- Economic Viability: Studies have shown that integrating a biorefinery with an existing sugar mill can lead to a high internal rate of return (IRR), with some scenarios demonstrating an IRR of over 50%. This makes the proposition attractive to potential investors.

The production of biomethanol creates a circular economy within the mill. The energy-rich bagasse, instead of being burned inefficiently, is converted into syngas through gasification. This syngas is then used to synthesize methanol. The leftover waste heat can still be used to generate electricity, maximizing the value obtained from every part of the sugarcane plant.

Lessons from Global Success: The Brazilian Model

South Africa doesn’t need to reinvent the wheel. The Brazilian sugar industry offers a powerful example of successful diversification and revitalization. Facing similar challenges in the 1970s and 80s, Brazil implemented its “Proálcool” program, which mandated the blending of ethanol with petrol (Coelho et al., 2015). This created a captive domestic market for bioethanol, transforming its sugarcane industry from a single-product commodity producer into a global leader in biofuel and sugar production.

Brazil’s success comes from its integrated biorefineries, called “usinas,” that produce both sugar and ethanol. The ability to switch production between the two based on market prices offers a vital buffer against price swings. They also create extra electricity from bagasse, which is sold back to the national grid. This boosts profitability and energy security. This model has shown to be strong and effective, and it offers a clear example of what South Africa can accomplish.

The Path Forward: Policy, Investment, and Innovation

To realize this vision, a concerted effort is needed from all stakeholders:

- Supportive Policies: The government must provide a stable and predictable policy environment. This includes implementing a mandatory biofuels blending policy to create a secure market for bioethanol and biomethanol. A moratorium on the sugar tax and a more robust anti-dumping policy are also crucial for the industry’s short-term survival. The South African government’s commitment to the Master Plan is a vital step, but swift action is needed to move from a conceptual framework to tangible projects.

- Investment and Infrastructure: The transition to a biorefinery model requires significant capital investment in new technologies and infrastructure. Public-private partnerships and targeted financial incentives will be essential to attract the necessary funding.

- Research and Development: Continuous innovation is key. South African research institutions, such as the Sugar Milling Research Institute (SMRI), must continue to explore new product opportunities and optimize conversion processes.

The revitalization of South Africa’s sugar industry is not just about saving a legacy sector; it’s about building a modern, diversified, and sustainable bioeconomy. By embracing a multi-product biorefinery model centered on high-value products like biomethanol, the industry can secure its future, create jobs, and contribute to a greener, more prosperous South Africa. The time for transformation is now.

citations

van der Merwe, M. (2024). How do we secure a future for the youth in South African agriculture? Agrekon. https://doi.org/10.1080/03031853.2024.2341511

Areeya, S., Panakkal, E. J., Kunmanee, P., Tawai, A., Amornraksa, S., Sriariyanun, M., Kaoloun, A., Hartini, N., Cheng, Y., Kchaou, M., Dasari, S., & Gundupalli, M. P. (2024). A Review of Sugarcane Biorefinery: From Waste to Value-Added Products. Applied Science and Engineering Progress. https://doi.org/10.14416/j.asep.2024.06.004

Formann, S., Hahn, A., Janke, L., Stinner, W., Sträuber, H., Logroño, W., & Nikolausz, M. (2020). Beyond Sugar and Ethanol Production: Value Generation Opportunities Through Sugarcane Residues. Frontiers in Energy Research, 8. https://doi.org/10.3389/FENRG.2020.579577

Economic and Environmental Comparison of the Monosodium Glutamate (MSG) Production Processes from A‐Molasses in an Integrated Sugarcane Biorefinery. International Journal of Chemical Engineering. https://doi.org/10.1155/2024/2077515.

Revitalizing the sugarcane industry by adding value to A‐molasses in biorefineries. Biofuels, 14. https://doi.org/10.1002/bbb.2122.

Coelho, S. T., Gorren, R. C. R., Guardabassi, P., Grisoli, R. P. S., & Goldemberg, J. (2015). Bioethanol from sugar: the brazilian experience. https://repositorio.usp.br/item/002711539