Rice Straw to Methanol in India: A Pathway to Green Energy and Economic Prosperity

India, a nation deeply rooted in agriculture, faces a persistent challenge with rice straw management. Every year, vast quantities of rice straw are generated after harvest, and a significant portion is traditionally disposed of through open field burning. This practice, while seemingly convenient for farmers, unleashes a cascade of environmental and health hazards. However, a promising solution is emerging from this challenge: converting rice straw into methanol. This innovative approach not only tackles the emission problem but also unlocks significant economic opportunities, paving the way for a greener and more prosperous India.

The Genesis of Emissions: Why Rice Straw Burning is a Problem

The emissions from rice straw burning are multifaceted and begin with the sheer volume of agricultural residue produced.Farmers face a narrow 2-3 week period to clear fields post-harvest, making burning the quickest method. India contributes a substantial 126.6 million tons of the 731 million tons of rice straw generated globally each year, with approximately 60% of it being burnt in fields. This widespread practice is driven primarily by the short window between rice harvesting and the sowing of the subsequent crop (often wheat), Burning is perceived as the cheapest and easiest option for managing crop residues, especially with the rise of mechanized harvesting(Kaur et al., 2022).

When rice straw is burnt in open fields, it undergoes incomplete combustion, releasing a cocktail of harmful pollutants into the atmosphere. These include:

- Greenhouse Gases (GHGs): While the CO2 released from burning is generally considered part of the natural carbon cycle (as it was sequestered by the plant during growth), the process also emits significant amounts of methane (CH4) and nitrous oxide (N2O). Both are far more potent greenhouse gases than CO2, contributing significantly to global warming. Studies, such as “Assessing rice straw availability and associated carbon footprint for methanol production: A case study in India” [https://pure.qub.ac.uk/files/627785589/1-s2.0-S0961953424005336-main.pdf], have estimated that open field rice straw burning can lead to GHG emissions of up to 7300 kg CO2-equivalent per hectare.

- Particulate Matter (PM2.5): Fine particulate matter, particularly PM2.5, is a major component of the smoke. These microscopic particles can penetrate deep into the lungs, leading to respiratory illnesses, cardiovascular problems, and even premature death. Delhi and surrounding regions frequently experience severe air pollution during the stubble burning season, highlighting the direct impact on public health.

- Toxic Gases: Carbon monoxide (CO), sulfur oxides (SOx), and nitrogen oxides (NOx) are also released. These gases are harmful to human health and contribute to smog formation and acid rain.

- Loss of Soil Health: Beyond air pollution, burning destroys valuable organic matter in the soil, leading to a loss of essential nutrients like nitrogen, phosphorus, and potassium. It also eradicates beneficial soil microorganisms, reducing soil fertility and increasing dependence on chemical fertilizers. This not only incurs higher costs for farmers but also degrades the long-term productivity of the land.

Mitigation through Valorization: The Rise of Rice Straw to Methanol

The solution to these emissions lies in valorizing rice straw – transforming it from a waste product into a valuable resource. One of the most promising avenues is its conversion into methanol. Methanol, a versatile chemical, can be used as a clean-burning fuel, a chemical feedstock for various industries, and a potential blend component for traditional fuels.

The primary technology for converting rice straw to methanol is gasification, followed by syngas conditioning and methanol synthesis. Here’s a simplified breakdown:

- Feedstock Preparation: Rice straw is collected, dried, and sometimes pre-treated (e.g., densified into pellets) to improve its handling and energy density.

- Gasification: The prepared rice straw is fed into a gasifier, where it undergoes partial oxidation at high temperatures (800-1100°C) in a controlled oxygen environment (Dahmen et al., 2017). This process converts the solid biomass into a synthesis gas (syngas) primarily composed of carbon monoxide (CO) and hydrogen (H2), along with some CO2 and other impurities.

- Syngas Cleaning and Conditioning: The raw syngas contains impurities like tar, ash, and other undesirable compounds. These are removed through various cleaning processes. The syngas composition is then adjusted to achieve the optimal H2:CO ratio for methanol synthesis.

- Methanol Synthesis: The cleaned and conditioned syngas is passed over a catalyst (typically copper-zinc-aluminum oxide) at high pressure and moderate temperature, leading to the chemical reaction that forms methanol (CO+2H2→CH3OH).

- Methanol Purification: The crude methanol is then purified through distillation to meet commercial specifications.

Another emerging technology is Hydrothermal Liquefaction (HTL), which can process wet biomass and produce a bio-crude that can then be upgraded to methanol or other fuels. The addition of co-solvents like methanol and catalysts can significantly improve the yield and quality of the bio-crude.

Mitigation’s Dual Benefit: A New Business Horizon

The transition from burning to methanol production offers a powerful mitigation plan with significant business implications:

- Environmental Impact Reduction: By converting rice straw, the harmful emissions associated with open burning are drastically reduced, leading to cleaner air, improved public health, and a tangible contribution to India’s climate change commitments. Bio-methanol has the potential to reduce GHG emissions by 67-74% compared to fossil methanol, as highlighted in the study by M.K. Ghosal and JyotiRanjan Rath, “Assessing rice straw availability and associated carbon footprint for methanol production: A case study in India”.

- Waste to Wealth: What was once considered a waste product becomes a valuable feedstock, generating economic value from agricultural residue. This aligns perfectly with the principles of a circular bioeconomy.

- Rural Economic Development: Establishing rice straw-to-methanol plants in rural areas creates new jobs for feedstock collection, processing, and plant operations. This provides additional income streams for farmers, who can sell their straw instead of burning it, and generates employment opportunities in their local communities.

- Energy Security: Producing methanol from domestic biomass reduces India’s reliance on imported fossil fuels, bolstering national energy security and saving valuable foreign exchange.

- Sustainable Industrial Feedstock: Bio-methanol can serve as a sustainable alternative to fossil-derived methanol, which is a key building block for numerous chemicals, plastics, and other industrial products.

Indian Companies Leading the Charge

While the rice straw to methanol sector is still nascent in India, several entities are actively exploring and implementing similar waste-to-energy models, particularly in the biofuel space.

- Jakson Green and NTPC: A notable development is the collaboration between energy transition company Jakson Green [https://www.jakson-green.com/] and NTPC (National Thermal Power Corporation) at the Vindhyachal Thermal Power Plant in Madhya Pradesh. This “first-of-its-kind” project in India successfully produces methanol from captured carbon dioxide (CO2) directly from flue gas emissions. While this specific project focuses on CO2 capture rather than direct rice straw to methanol, it demonstrates a strong commitment to green methanol production and sets a precedent for utilizing waste streams for fuel synthesis. The expertise gained in methanol synthesis and handling could be readily applied to biomass-to-methanol projects. NTPC’s motivation is driven by its vision to be a leading power utility with a strong focus on sustainability and diversifying its energy portfolio. The project aligns with India’s “Methanol Economy” vision to reduce carbon emissions and reliance on crude oil imports.

- Steamax India (steamaxindia.com) is a growing company focused on creating new technologies to turn rice straw into methanol. They use thermochemical processes like pyrolysis and gasification to change agricultural waste, such as rice straw, into high-quality methanol fuel. By improving feedstock handling and streamlining processes, Steamax India aims to boost production efficiency and reduce environmental impact, supporting local bioeconomy growth. Their method follows recent research on converting rice straw to methanol, highlighting cost savings, lower carbon emissions, and scalable industrial use. For more details about their technologies and projects, visit their official website: https://steamaxindia.com.

- CSIR-Indian Institute of Petroleum (IIP): Research institutions like CSIR-IIP [https://www.iip.res.in/] are actively involved in developing and optimizing technologies for converting rice straw into valuable chemicals, including methanol and monomeric phenols, using processes like hydrothermal liquefaction. Their research is crucial for making these technologies more efficient and economically viable. Their mission is to develop deployable, resource-efficient, and environment-friendly technologies for sustainable use of renewable carbon resources.

- Gujarat Enviro Protection and Infrastructure (GEPIL): Gujarat Enviro Protection and Infrastructure (GEPIL) [https://www.gepil.in/] is a private sector company focused on environmental infrastructure projects, including hazardous waste management, municipal solid waste management, and sustainable alternate fuel production. While their primary focus is broader waste management, their expertise in converting waste into alternate fuels, particularly through co-processing in cement plants, positions them well for future ventures into rice straw to methanol. Their work demonstrates a commitment to transforming waste into valuable resources, minimizing environmental impact, and supporting a circular economy. Their motivation is rooted in creating large-scale industrial solutions for waste management and contributing to a cleaner and greener environment across India. They achieve profitability by offering comprehensive, end-to-end waste management solutions that generate value from waste streams, adhering to strict environmental compliance, and leveraging their extensive experience and infrastructure across multiple states.

The Path to Perfect Profitability

For rice straw to methanol conversion to be perfectly profitable, several factors need to align:

- Efficient Feedstock Supply Chain: This is perhaps the most critical element. An optimized collection and transportation network for rice straw is essential to minimize costs. This involves:

- Mechanized Collection: Utilizing balers and other machinery to efficiently collect and densify straw.

- Farmer Engagement: Incentivizing farmers to sell their straw instead of burning it through fair pricing and reliable procurement. Government subsidies for straw collection equipment could also play a role.

- Logistics Optimization: Strategic plant locations close to high rice-producing areas to reduce transportation distances and costs.

- Technological Advancement & Scale:

- Improved Conversion Efficiency: Continued research and development to enhance the efficiency of gasification and methanol synthesis processes, maximizing methanol yield per ton of straw.

- Economies of Scale: Building larger capacity plants can reduce per-unit production costs.

- Supportive Government Policies:

- Biofuel Blending Mandates: Clear and ambitious blending mandates for bio-methanol in fuel or industrial applications create a guaranteed market demand.

- Financial Incentives: Subsidies, tax breaks, and low-interest loans for setting up rice straw to methanol plants, as well as for the purchase of bio-methanol, can significantly de-risk investments. The Indian government’s emphasis on biofuels for energy independence and reducing logistics costs, as highlighted by Union Minister Nitin Gadkari, indicates a supportive policy environment.

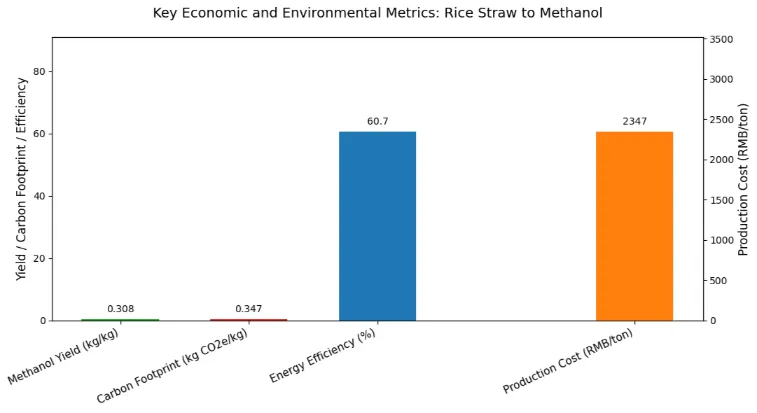

- Rice straw-to-methanol conversion demonstrates promising economic and environmental potential, with methanol yields around 0.308 kg per kg of rice straw and energy efficiencies reaching up to 60.7% through integrated processes with CO₂ recycling. Plant scales vary from laboratory to industrial, such as 50,000 tons/year in China and over 1,200 tons/year in India. Production costs in China (2009) range between 2,347 and 2,685 RMB/ton, with environmental costs estimated at roughly 285 RMB/ton, which is about 76.84 yuan/ton cheaper than coal-based methanol, indicating competitive cost advantages. India’s production potential is approximately 1,215 tons/year from 4,411 tons of rice straw, and the carbon footprint of biomethanol is significantly lower at 0.347 kg CO₂e/kg—much less than fossil methanol. Economic profitability is driven by large-scale feedstock supply, optimized logistics, integration of pyrolysis, gasification, and methanol synthesis processes, and leveraging environmental credits from low carbon emissions. Further cost reductions and emission cuts are possible through logistics optimization and employing renewable or self-generated energy Deka, T., Budhiraja, B., Osman, A., Baruah, D., & Rooney, D. (2025). Overall, rice straw biomethanol holds strong prospects for economically viable and environmentally sustainable alternative fuel production in regions with abundant biomass and supportive policies.

- Carbon Credits: The ability to earn carbon credits for reducing GHG emissions through straw valorization adds an additional revenue stream.

- Market Demand and Pricing:

- Competitive Pricing: Ensuring that bio-methanol can compete with fossil methanol in terms of price. This can be achieved through a combination of efficient production and policy support.

- Diversified Offtake: Exploring various applications for methanol, including fuel blending, chemical manufacturing, and potentially hydrogen production, to ensure stable demand.

In conclusion, the conversion of rice straw to methanol in India presents a powerful synergy of environmental mitigation and economic opportunity. By addressing the pressing issue of agricultural waste burning and simultaneously fostering a domestic source of clean fuel and chemicals, India can move closer to its goals of energy independence, a cleaner environment, and a thriving rural economy. The success of pioneering companies and the increasing government focus on waste-to-energy initiatives signal a promising future where rice straw, once an environmental burden, becomes a cornerstone of India’s sustainable development

citations

Kaur, M., Malik, D. S., Malhi, G. S., Sardana, V., Bolan, N., Lal, R., & Siddique, K. H. M. (2022). Rice residue management in the Indo-Gangetic Plains for climate and food security. A review. Agronomy for Sustainable Development, 42(5). https://doi.org/10.1007/s13593-022-00817-0

Dahmen, N., Henrich, E., & Henrich, T. (2017). Synthesis Gas Biorefinery (Vol. 166, pp. 217–245). Springer, Cham. https://doi.org/10.1007/10_2016_63

. Assessing rice straw availability and associated carbon footprint for methanol production: A case study in India. Biomass and Bioenergy. https://doi.org/10.1016/j.biombioe.2024.107580.