Introduction: Why Sustainable Biorefineries Matter for South Africa

With rising energy challenges, environmental harm, and economic pressures, South Africa faces a crucial moment in rethinking its energy and industrial future. Sustainable biorefineries provide an innovative solution that uses the country’s abundant biomass resources, especially sugarcane residues, to create renewable fuels like bio-methanol. This approach fits with global trends to reduce reliance on fossil fuels while encouraging a circular bioeconomy that supports rural development and job creation 215.

By converting agricultural waste into methanol, South Africa can greatly lessen greenhouse gas emissions, reduce waste disposal issues, and strengthen its industrial sector. This blog explores the technical, environmental, economic, and social aspects of setting up sustainable methanol biorefineries using sugarcane bagasse and trash, highlighting their strategic importance and feasibility within South Africa’s bioeconomy roadmap 216.

The Sugarcane Industry in South Africa: A Biomass Powerhouse

Sugarcane Production and Residue Availability

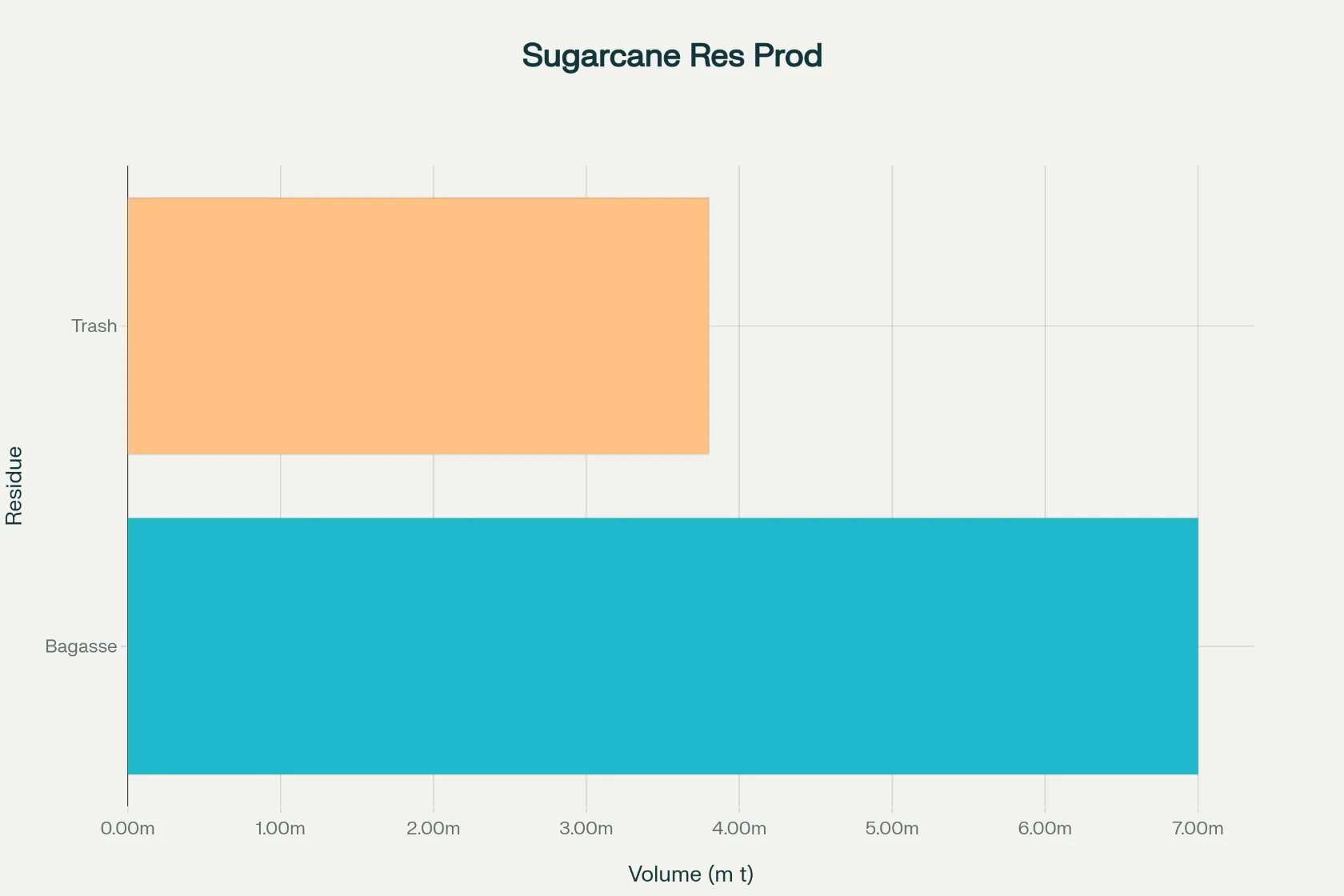

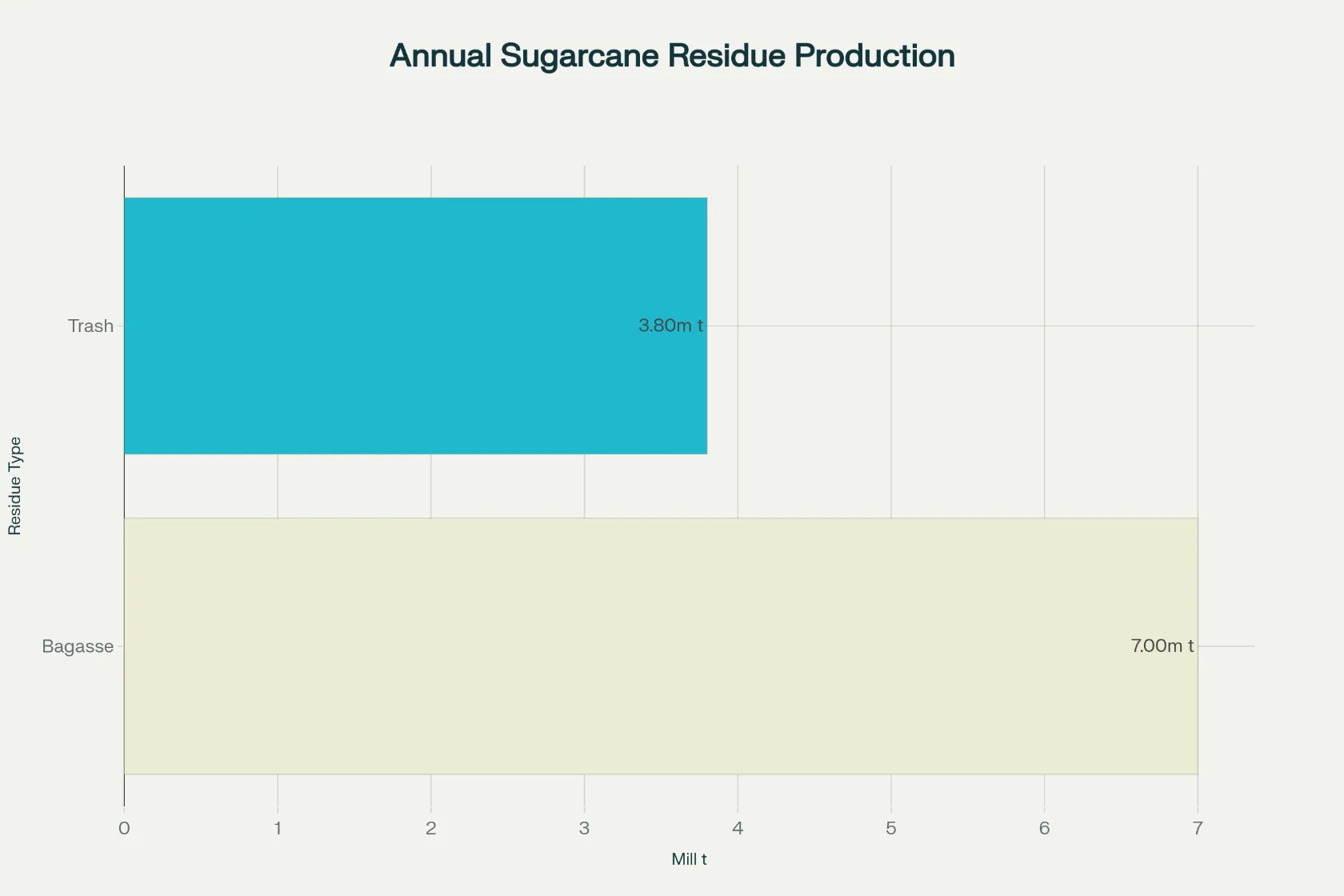

South Africa’s sugarcane sector is a strong agricultural foundation generating around 19 million tons of cane each year, mainly in KwaZulu-Natal and Mpumalanga. Processing this large quantity yields about 7 million tons of bagasse, which is a fibrous byproduct, along with significant amounts of trash (leaf residues). Typically seen as waste, these residues currently create environmental issues due to poor disposal, but they also represent an untapped biomass resource for sustainable biorefineries 215.

Locating biorefineries at existing sugar mills can greatly cut logistics costs and utilize established infrastructure, making methanol production from bagasse both sensible and affordable. The large quantity and geographic concentration of sugarcane residues give South Africa an excellent feedstock advantage that’s hard to match with other biomass types 27.

Why Valorize Sugarcane Residues?

- Waste reduction: Reduce environmental problems linked to burning or dumping residues.

- Green energy: Create renewable fuels and chemicals, cutting fossil fuel dependence.

- Rural development: Promote local job creation and diversify farmer income streams.

- Support circular economy: Turn waste into valuable products and close resource loops 25.

Methanol Production from Sugarcane Residues: Technology Overview

Key Process Stages

The process of converting lignocellulosic sugarcane residues into methanol involves several connected steps:

- Biomass Pre-treatment: Drying reduces moisture from about 45% to 15% and size reduction prepares the feedstock for gasification.

- Gasification: Thermochemical partial oxidation changes bagasse and trash into synthetic gas (syngas) rich in hydrogen (H₂) and carbon monoxide (CO).

- Syngas Cleaning & Conditioning: Removing contaminants like sulfur and tars protects the catalysts and modifies the gas composition.

- Methanol Synthesis: A catalytic reaction, usually with Cu/Zn/Al catalysts, turns conditioned syngas into methanol under high pressure and temperature.

- Purification: Distillation and separation produce high-purity methanol ready for further use 2516.

Advances in Gasification Technology

South Africa’s biorefineries can utilize established gasification technologies like fixed bed, fluidized bed, and drag bed reactors. Each technology has its own trade-offs in terms of efficiency, tar production, and scalability:

- Downdraft fixed bed gasifiers: High tar removal and simpler cleaning.

- Circulating fluidized bed (CFB): More even combustion and higher efficiency, but complicated operation.

- Drag bed reactors: High throughput and nearly tar-free syngas 25.

Tailoring gasifiers for fibrous sugarcane bagasse enhances conversion rates and supports economic viability.

Cutting-edge Catalysts for Methanol Synthesis

Commercial methanol synthesis catalysts commonly use copper-based systems (Cu/Zn/Al₂O₃), often improved with promoters like cerium-zirconium oxides for better activity and durability. Ongoing research in South Africa focuses on catalysts that can handle impurities from biomass-derived syngas and enable CO₂ utilization, which is essential for sustainability and carbon-negative products 216.

Environmental Benefits of Sugarcane-Based Methanol Biorefineries

Significant Reduction of Greenhouse Gas Emissions

Compared to fossil methanol, biomass-based methanol can cut lifecycle greenhouse gas emissions by 25-60%. Studies even show negative carbon footprints under optimal conditions. This directly supports South Africa’s climate commitments and helps move the country toward a low-carbon economy 216.

Efficient Waste Valorization and Pollution Mitigation

By converting waste residues into useful fuel, biorefineries address the significant environmental issue of biomass residue disposal, which otherwise causes air pollution and pest issues. Also, modern biorefineries use integrated heat and power systems to reduce overall emissions and improve energy efficiency 25.

Water and Land Use Considerations

South Africa’s water scarcity requires careful resource management. Sustainable biorefineries focus on using existing residues instead of expanding farmland, limiting water use and food-vs-fuel conflicts. Applying precision agriculture and water-efficient practices in the sugar industry can also help ease environmental trade-offs 215.

Economic Viability and Market Potential for Methanol from Sugarcane Residues

Techno-economic Insights and Investment Returns

Feasibility studies show that methanol biorefineries paired with sugar mills can achieve internal rates of return (IRR) around 15-17%, making them appealing investment options. However, competing with fossil methanol pricing remains a challenge, with bio-methanol currently costing 1.5 to 4 times more 27.

Strategies to Overcome Cost Barriers

- Government Incentives: Production subsidies, tax breaks, and grants can help close price gaps and reduce investment risks.

- Multi-product Biorefineries: Producing bioelectricity, other chemicals (like ethanol and lactic acid), and feedstocks can improve economic stability.

- Technological Improvements: Better gasifier efficiency and catalyst performance can bring down operational costs 27.

Global and Local Market Opportunities

With global methanol demand expected to exceed 500 million tons per year by 2050, South Africa stands to gain both domestically and through exports. Building a bio-methanol industry also enhances energy security and aligns with global shifts towards cleaner fuels 215.

Social Impacts: Empowering Rural Communities and Addressing Equity

Job Creation and Skills Development

Building and running sugarcane biorefineries can create thousands of direct and indirect jobs, especially in rural areas where sugarcane is grown. This supports poverty reduction and skill development in communities often left out of industrial growth 715.

Enhancing Rural Economies and Smallholder Involvement

Inclusive value chains allow small-scale farmers to engage in residue collection and supply, diversifying their incomes beyond traditional sugar sales. Fair contracts and training programs are vital for equity 715.

Mitigating Food-vs-Fuel Concerns

Using residues instead of dedicated energy crops avoids direct competition with food production, reducing food security risks. Combined with sustainable water use policies, this approach promotes balanced social and ecological development 215.

Policy and Regulatory Framework: Accelerating South Africa’s Bioeconomy

Current Support and Gaps

South Africa’s Bio-economy Strategy and National Development Plan provide a basis for supporting biorefineries and renewable fuels. However, clearer and more consistent incentives are needed to encourage private investment and commercialization 15.

Recommendations for Policy Makers

- Stable incentives: Long-term subsidies and guaranteed purchase agreements.

- Streamlined regulations: Simplify licensing and environmental permits.

- R&D Funding: Increase funding for catalyst and gasification technology development.

- Infrastructure Support: Enhance biomass logistics and grid integration 15.

Challenges and Future Outlook

The creation of sugarcane residue methanol biorefineries faces obstacles, including managing the biomass supply chain, high initial costs, and technical complexity. Overcoming these challenges requires:

- Strong public-private partnerships involving government, academia, and industry.

- Pilot and demonstration projects to prove technical and economic feasibility.

- Capacity building for the local workforce and technology transfer 215.

South Africa’s unique combination of sugarcane biomass availability, renewable energy potential, and policy ambition positions it strongly to lead in sustainable methanol production. This will support the growth of a circular bioeconomy and a resilient energy future.

Conclusion: A Strategic Path Forward for South Africa

Using sugarcane residues for methanol biorefineries offers South Africa an effective strategy to tackle energy shortages, lower carbon emissions, and promote rural development. With proven technologies and ample resources, scaling bio-methanol production aligns with national and global sustainability goals.

To achieve this potential, focused efforts on technology optimization, policy support, multi-product biorefining, and community engagement are essential. South Africa can convert agricultural waste into a green energy and chemical hub, setting an inspiring example for sustainable development in Africa and beyond.

For more information on sugarcane biorefineries, visit:

By leveraging sugarcane residues, South Africa can unlock a sustainable future one where waste becomes wealth, energy becomes cleaner, and rural communities thrive.

This information offers important insights into South Africa’s expanding biorefinery sector. It highlights key players, their production capabilities, and new methods for using resources sustainably. By learning about these industry leaders and research initiatives, stakeholders can spot chances for investment, collaboration, or adopting new technologies in the bioeconomy. The detailed profiles, which include production figures and official links, serve as a trustworthy reference for anyone looking into renewable energy and circular economy solutions in South Africa, including policymakers, potential investors, and academic researchers.

Top 5 Large-Scale Biorefineries in South Africa: Current Players and Innovations

South Africa’s biorefinery sector is still developing. Most large-scale operations are part of existing industries like pulp and paper and sugar production. Standalone, multi-product biorefineries are uncommon. However, several key players are adopting biorefinery principles by converting biomass into energy, chemicals, and materials to improve sustainability and economic value.

Here’s a look at the top five notable biorefinery initiatives and facilities in South Africa:

1. Sappi – Forest Biorefinery Leader

Name: Sappi (Saiccor & Ngodwana Mills)

Description:

Sappi, known as a pulp and paper giant, is moving toward a forest biorefinery model. They extract high-value biomaterials from wood. Their operations produce dissolving wood pulp (DWP) and are expanding into nanocellulose (Valida), lignin, furfural, xylose, and organic acids. Their Ngodwana Mill hosts South Africa’s first biomass power plant under the Renewable Energy Independent Power Producer Procurement Programme (REIPPPP).

Production Details:

- 1.15 million tons of dissolving pulp annually (Southern Africa operations).

- Biomaterial production (lignin, nanocellulose) is growing but not yet fully commercial.

2. Illovo Sugar Africa – Sugarcane-Based Biorefinery

Name: Illovo Sugar South Africa (Pty) Ltd.

Description:

Illovo, a leading sugar producer, processes sugarcane into raw, brown, and refined sugar. They also produce furfural, ethyl alcohol (from molasses), and lactulose. Their operations follow biorefinery principles by turning waste streams into chemicals and energy.

Production Details:

- 550,000+ tons of sugar annually.

- 65,000+ litres of high-grade ethanol per year for beverages.

3. DSI-CSIR Biorefinery Industry Development Facility (BIDF) – R&D Hub

Name: DSI-CSIR Biorefinery Industry Development Facility (BIDF)

Description:

This government-funded R&D facility in Durban supports the development of biorefinery technology. It works with forestry, agriculture, and waste sectors to produce biofuels, biochemicals, and biomaterials. While not a commercial plant, it plays a crucial role in improving South Africa’s biorefinery capabilities.

Production Details:

- Focuses on pilot-scale and technology development, not commercial output.

Learn more:

CSIR Biorefinery Industry Development Facility4. Ngodwana Energy Biomass Project (Sappi) – Renewable Energy from Biomass

Name: Ngodwana Energy Biomass Project (Sappi’s Ngodwana Mill)

Description:

Located at Sappi’s Ngodwana Mill, this biomass power plant generates renewable electricity from forestry waste. It contributes to South Africa’s energy transition.

Production Details:

- One of the largest biomass-to-energy projects in the country.

Learn more:

Sappi Southern Africa5. Industrial Biogas Plants – Waste-to-Energy Solutions

Name: Various industrial biogas plants

Description:

Several municipal and agricultural biogas plants convert organic waste, sewage, and agro-residues into biogas for electricity, heat, and transport fuel. While smaller in scale, they represent key biorefinery applications in South Africa’s circular economy.

Production Details:

- Decentralized operations, with no single dominant player.

Conclusion

South Africa’s biorefinery sector is still emerging. Most large-scale activities are linked to existing industries like pulp and paper (Sappi) and sugar (Illovo). Research initiatives like the CSIR’s BIDF are critical for future growth. Biomass energy and biogas projects show practical waste-to-value applications.

As technology advances, we expect more standalone biorefineries producing biofuels, biochemicals, and biomaterials at scale. For now, these five players lead the way in South Africa’s bioeconomy transition.