IBiomethanol from Corn Straw in China

The search for sustainable energy solutions is more urgent than ever. Biomethanol from Corn Straw in China is becoming a promising option in the global move away from fossil fuels. A detailed life cycle analysis (LCA) highlights notable environmental benefits, despite some economic challenges, making this biofuel a key part of China’s energy future.

The Green Advantage: Environmental Benefits of Corn Straw Biomethanol

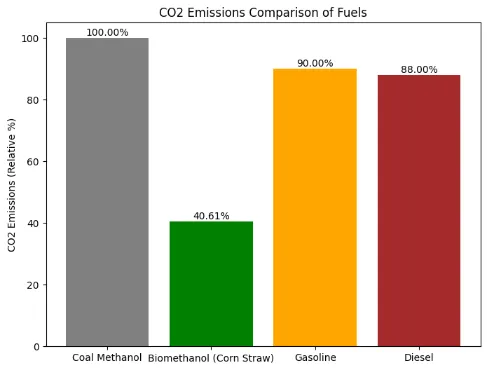

One of the main reasons to support biomethanol from corn straw in China is its significant reduction in environmental impact. Studies show that its production results in 59.39% lower CO2 emissions compared to coal derived methanol. This significant reduction shows corn straw biomethanol’s potential as a cleaner fuel option.

In addition to CO2, studies of corn straw bioenergy show greenhouse gas emissions ranging from 82 to 439 kilograms CO2 equivalent per ton of straw. Other important impact categories include fossil fuel depletion, global warming potential, toxicity, acidification, eutrophication, ozone depletion, photochemical ozone creation potential, and human toxicity potential.

Moreover, analyses reveal that converting corn straw can lower particulate matter emissions by up to 98%. This is particularly important as air quality continues to be a major concern in many areas. Corn straw also outperforms feedstocks like rice and soybean straw in terms of greenhouse gas emissions and energy balance. The flash pyrolysis method, for instance, has achieved coal savings up to 78.02% when processing corn straw.

Across ten different studies, all reported positive effects on greenhouse gas or carbon dioxide emissions, or global warming potential. For example, global warming potential dropped by 10 to 97% when compared to gasoline and 4 to 96% when compared to diesel. Absolute reductions in CO2-equivalent emissions were also significant, with figures surpassing 170 million tonnes annually in some national assessments.

Economic Realities: Costs and Opportunities

While the environmental benefits are evident, the economic situation of biomethanol from corn straw in China is more complex. The production cost of biomethanol from corn straw is reported to be 24.46% higher than that of coal methanol. The cost of biomethanol is around US$502.0 per ton.

However, certain applications show clear economic advantages. In maritime settings, for example, the fuel costs 14.81% less per kilometer than diesel, and it generates 54.01% lower CO2 emissions per kilometer. This indicates that specific industry sectors could take advantage of biomethanol’s cost benefits.

The economic viability also improves with potential by product savings, valued at 23.9 billion RMB in some instances. Additional economic benefits include biomethanol having the lowest emergy per unit of particulate matter and the fact that a carbon tax would benefit bioethanol. Advanced biofuels also offer a new income source for farmers. It is worth noting that economic reporting across studies varied, with many not discussing specific advantages or drawbacks.

Energy Efficiency: A Closer Look

The efficiency of producing biomethanol from corn straw is another key factor examined through life cycle analysis. The production system requires 510,200 megajoules per ton of corn straw. Despite this energy requirement, studies show positive energy balances for biofuels made from corn straw.

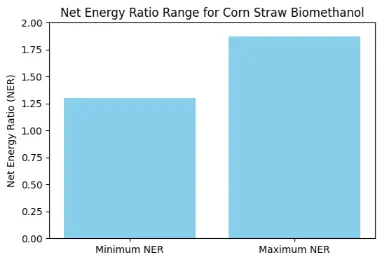

Net energy ratios (NER) for corn straw bioenergy typically range from 1.30 to 1.87. For example, one study indicated a net energy balance (NEB) of 6,902 megajoules per megagram of ethanol and a net energy ratio of 1.30. These numbers demonstrate that corn straw can produce more energy than is used in its production, although efficiency can vary based on the feedstock characteristics and conversion processes used.

Research Behind the Insights: How We Know This

The insights regarding Biomethanol from Corn Straw in China come from thorough academic research. A dedicated search was conducted using the phrase “Biomethanol from Corn Straw in China: A Life Cycle Insight” across over 126 million academic papers. Papers were selected based on specific criteria, including a focus on corn straw as a main feedstock, analysis within the Chinese context, inclusion of life cycle assessment (LCA) data, quantitative information on material flows, energy use, or environmental impacts, and examination of complete production processes grounded in empirical evidence.

A large language model was used for data extraction, gathering detailed insights on LCA methodology, biomass feedstock characteristics, environmental impact metrics, economic cost analysis, and potential industry applications. This systematic method ensures that the findings are solid and thorough.

Regional Perspectives & Future Potential

The studies explored various regions within China, from national-level assessments to analyses of multiple provinces (nine or thirty) and specific provinces like Heilongjiang. This regional variety offers a nuanced view of the potential and challenges in different areas.

Importantly, corn straw has been shown to outperform rice and soybean straw concerning greenhouse gas emissions and energy balance, making it a particularly appealing feedstock. Flash pyrolysis was singled out as the most effective straw treatment for coal savings. The potential for large-scale greenhouse gas reduction is strongest in provinces with abundant surplus stover and efficient supply chains. This suggests that optimizing collection and logistics will be essential to maximize the benefits of biomethanol from corn straw in China.

Conclusion

In conclusion, biomethanol from corn straw in China represents a significant step toward a more sustainable energy future. While the higher production costs compared to coal-derived methanol present challenges, the large reductions in CO2 and particulate matter emissions, combined with promising economic benefits in targeted applications and the potential for valuable by product savings, highlight its importance. Ongoing research and strategic implementation can further unlock the full potential of this renewable resource in China’s energy landscape.