China Path to Low-Carbon Shipping: Biomethanol Fuel from Corn Straw

The colossal cargo ships that traverse our oceans play a vital role in global trade, carrying 80% of the world’s goods. However, their reliance on heavy fuel oil significantly contributes to greenhouse gas emissions, complicating the fight against climate change. As the need for decarbonization intensifies across various industries, China is taking a bold and innovative approach in its maritime sector. Moving past traditional solutions, the country is using an unexpected resource—corn straw—to produce biomethanol, a promising low-carbon fuel that could transform shipping and set a global example for a greener maritime future.

From Field Waste to Fueling Giants: An Innovation Rooted in the Earth

Picture the expansive fields in China’s agricultural regions, where harvests provide not only food but also substantial amounts of leftover biomass—corn straw. For years, this byproduct was either left to rot or burned, causing air pollution and wasting a potential resource. Now, imagine a process that combines traditional agricultural waste with modern green technology, revitalizing this seemingly discarded material. China is creatively repurposing corn straw to create biomethanol, a liquid fuel with a much lower carbon footprint than conventional marine fuels.

This innovative strategy addresses several challenges at once. It provides a sustainable alternative to fossil fuels in a sector known for its difficulty in reducing carbon emissions. It also creates economic incentives for farmers to gather and supply corn straw, turning waste into a prized resource and potentially bolstering rural economies. Most importantly, it places China in a leading role in green shipping, showing its dedication to climate goals and showcasing its technological strength.

The conversion of corn straw into biomethanol is an interesting chemical process. The lignocellulosic biomass of corn straw, which contains cellulose, hemicellulose, and lignin, undergoes several complex steps:

- Pretreatment: First, the raw corn straw is pretreated to break down its structure, allowing easier access to cellulose and hemicellulose. Various methods, including physical, chemical, and biological pretreatments, are used to optimize this stage.

- Gasification: Next, the pretreated biomass is heated in a controlled environment with limited oxygen, undergoing gasification. This process converts the organic material into syngas, a mixture mainly made up of carbon monoxide (CO), hydrogen (H₂), and carbon dioxide (CO₂).

- Syngas Cleaning and Conditioning: The raw syngas contains impurities that can hinder the next catalytic stage. Therefore, it is carefully cleaned to remove particulates, sulfur compounds, and other contaminants, while also adjusting the hydrogen to carbon monoxide ratio for optimal methanol synthesis.

- Methanol Synthesis: The core of the process involves converting the conditioned syngas into methanol through a catalytic reaction, typically utilizing a catalyst such as copper, zinc oxide, and alumina, all while applying high pressure and temperature. The resulting methanol is then purified through distillation to meet fuel-grade standards.

Although the technical details are intricate, the basic idea is straightforward: capture carbon from agricultural waste and switch it into a cleaner fuel. This reflects the principles of a circular economy, where waste is minimized and resources are used efficiently.

A Triple Win: Sustainability, Circularity, and Climate Action

China’s commitment to using corn straw-based biomethanol for shipping is not only a technical achievement; it’s also a strong message about its dedication to sustainability and climate action. The environmental benefits are numerous:

China is exploring the use of corn straw-derived biomethanol as a marine fuel to decarbonize its shipping sector, aiming for a “triple win” of sustainability, circularity, and climate action. This approach leverages abundant agricultural residues, reduces greenhouse gas emissions, and supports rural economies.

Environmental and Climate Benefits

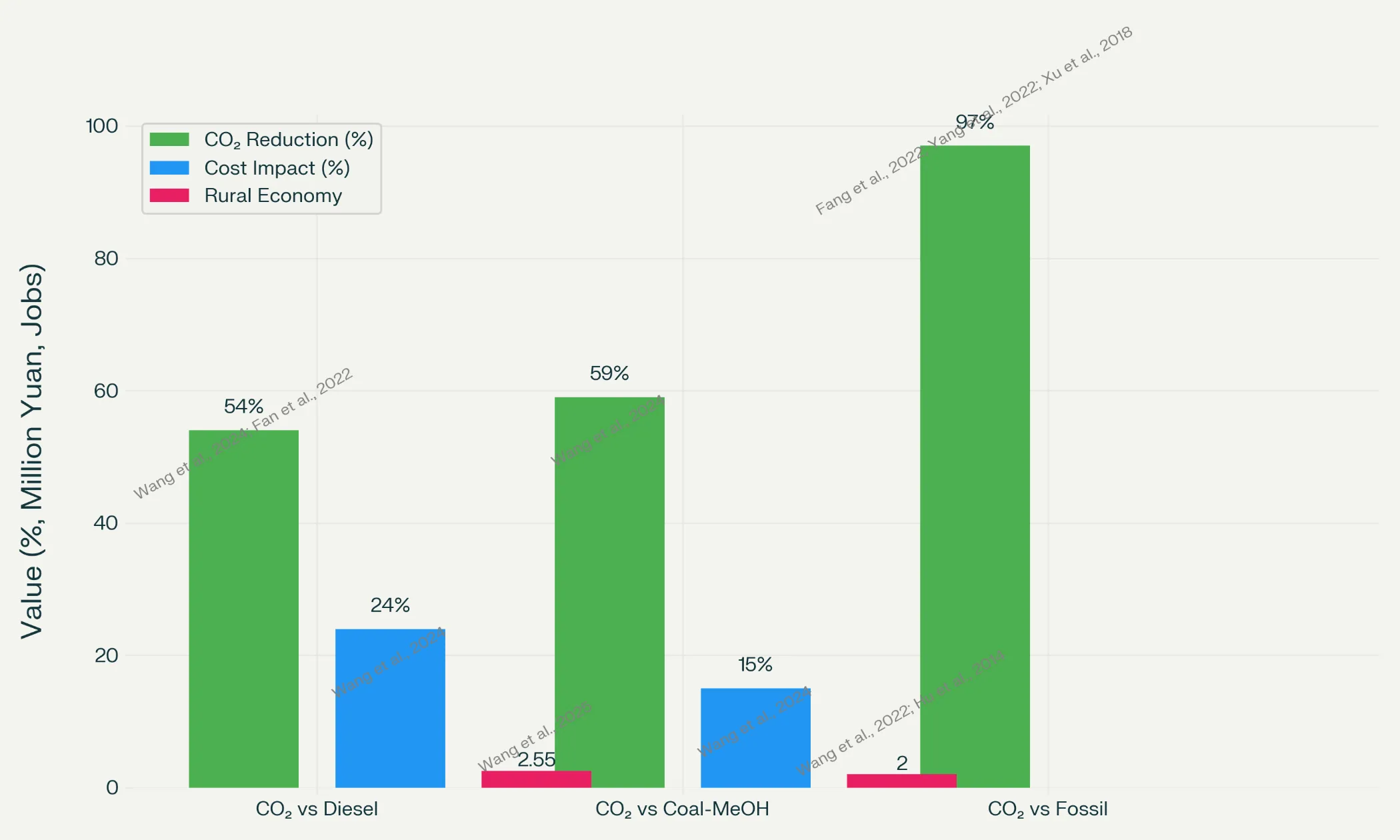

Biomethanol from corn straw can reduce CO₂ emissions by 54–59% per kilometer compared to conventional marine diesel, and by 59% compared to coal-to-methanol, making it a strong candidate for low-carbon shipping (Wang et al., 2024; Fan et al., 2022). Life cycle assessments show that using crop straw for bioenergy can cut greenhouse gas emissions by up to 97% compared to fossil fuels, depending on the conversion pathway and region (Fang et al., 2022; Yang et al., 2022; Xu et al., 2018). Integrating renewable electricity or self-generation at methanol plants can further lower emissions, meeting stringent EU standards (Wang et al., 2024).

Economic and Social Impacts

While biomethanol production costs are about 24% higher than coal-based methanol, its use in shipping can reduce per-kilometer costs by nearly 15% compared to diesel (Wang et al., 2024). Each million yuan invested in straw-based biofuels can generate 2.55 million yuan in economic output and create nearly two full-time jobs, supporting rural development and supply chain actors (Wang et al., 2025; Wang et al., 2022; Hu et al., 2014).

Circularity and Supply Chain Considerations

Circular economy principles are advanced by converting agricultural waste into fuel, reducing open-field burning and pollution (Li et al., 2024; Hu et al., 2014). Efficient supply chain management—including feedstock collection, transport, and processing—is critical for maximizing sustainability and economic returns (Wang et al., 2022; Yang et al., 2022). Onboard carbon capture and closed-loop fuel cycles could further enhance circularity, though they currently increase costs (Charalambous et al., 2025).

| Paper | Focus | Key Insight | Year |

|---|---|---|---|

| (Wang et al., 2024) | Biomethanol LCA | Major CO₂ and cost savings in shipping | 2024 |

| (Wang et al., 2025) | Triple-bottom-line | Economic, social, and environmental benefits | 2025 |

| (Charalambous et al., 2025) | Circular marine fuels | Onboard carbon capture feasibility | 2025 |

| (Wang et al., 2022) | Supply chain modeling | Optimizing straw logistics and profits | 2022 |

Figure 1: biomethanol, supply chains, and climate impacts.

Corn straw-based biomethanol offers significant climate, economic, and circularity benefits for China’s shipping sector. While challenges remain in cost and supply chain optimization, the approach aligns with national sustainability and decarbonization goals, supporting a robust “triple win” strategy.

In addition to environmental benefits, this initiative brings significant economic and social advantages. Farmers in corn-producing areas can earn extra income by supplying corn straw, which promotes rural economic growth. The expansion of the biomethanol industry can create new jobs in production, logistics, and research. Shipping companies that switch to biomethanol can enhance their environmental image, attracting eco-conscious customers while complying with increasingly strict international emission regulations.

Voices from the Ground and the Helm: Humanizing the Green Transition

The journey from cornfield to cargo ship involves more than just technological progress; it’s a narrative filled with human effort. Imagine Mr. Li, a farmer in Shandong province, who once saw leftover corn stalks as a nuisance. Thanks to local cooperatives and bioenergy firms, his corn straw now has value, adding to his financial security. He realizes his work contributes to a larger cause—a cleaner future for his nation.

On the industrial side, consider the engineers at a cutting-edge biorefinery, diligently perfecting the biomethanol production process. They are motivated by the challenge of scaling production, enhancing efficiency, and ensuring the biofuel’s quality meets the shipping industry’s demands. Their creativity is what drives this green shift.

Think about Captain Zhang, steering a large container ship across the South China Sea. His vessel runs on a mix of conventional fuel and biomethanol, serving as a pilot project that showcases the viability of this alternative fuel in real-world situations. He knows that the future of his industry depends on embracing cleaner energy sources and feels proud to be part of this groundbreaking initiative.

These individual and collective efforts highlight the complex nature of this transition, showing how innovation at the technological level can yield real benefits for communities and industries.

Navigating the Technical Seas: Production, Efficiency, and Scalability

While the potential of corn straw-based biomethanol is substantial, understanding its technical elements is vital. The conversion efficiency, the energy balance throughout the entire value chain (from harvesting to burning), and the scalability of production are important factors.

Current methods for turning lignocellulosic biomass into biomethanol are constantly improving to enhance yields and cut costs. Research focuses on optimizing pretreatment techniques, improving gasification and catalytic processes, and developing stronger, more affordable catalysts.

Scalability is also crucial. China is a major corn producer, generating large amounts of corn straw each year. However, logistical issues involving the collection, storage, and transportation of this distributed resource need to be resolved to ensure a steady supply of feedstock for large-scale biomethanol operations. Investing in infrastructure, such as collection networks, storage facilities, and transportation systems, is crucial.

Additionally, biomethanol’s compatibility with existing ship engines and fueling infrastructure provides a major benefit. It can be used in modified conventional engines with minimal alterations, making the transition less disruptive and more cost-effective compared to other alternative fuels that might necessitate entirely new engine designs and fuel delivery methods.

A Global Compass: Setting a Course for International Shipping

China’s groundbreaking work in using corn straw for biomethanol production could have a significant impact beyond its borders. The International Maritime Organization (IMO) has set ambitious goals for lowering greenhouse gas emissions from global shipping, aiming for at least a 50% reduction by 2050 compared to 2008 levels while pushing for full elimination as soon as possible this century. To meet these objectives, the industry needs a varied range of low-carbon and zero-carbon fuels.

China’s innovative approach serves as a strong example for other countries with significant agricultural biomass resources. Regions that produce large quantities of crops like wheat, rice, or sugarcane could potentially adopt similar technologies to make sustainable biofuels from their agricultural waste.

Moreover, developing standards and regulations for biomethanol as a marine fuel, partly driven by China’s early adoption, could facilitate broader acceptance and use in the global shipping industry. Collaboration in research, technology sharing, and the establishment of international best practices will be key to unlocking the full potential of this and other sustainable biofuels.

Charting a Greener Horizon: The Future is Fueled by Innovation

The quest to decarbonize global shipping is a complex and challenging effort, but China’s use of corn straw to create biomethanol offers hope. It showcases the strength of human creativity, the opportunities within a circular economy, and a nation’s commitment to a more sustainable future.

This is more than a technological breakthrough; it represents a fundamental shift. It indicates a transition away from a “take-make-dispose” approach towards a more sustainable and circular model. It highlights the connections among different sectors—agriculture, energy, and transportation—as they work together toward a shared goal: a healthier planet.

China’s journey toward low-carbon shipping, fueled by the innovation of converting corn straw into biomethanol, shows how human resourcefulness can address some of the world’s most pressing challenges. It is a story about turning waste into value and leveraging nature’s bounty to drive global trade in a cleaner, more sustainable manner. As the world observes, this pioneering effort could very well steer shipping toward a greener future, one in which the giants of the sea navigate a horizon illuminated by sustainable biofuels.

Looking ahead, the outlook for biomethanol in shipping seems bright. Ongoing advancements in production methods, supportive government actions, and rising demand for eco-friendly transportation options will likely drive further growth in this sector. The image of massive cargo ships powered in part by energy collected from humble corn stalks is not just a dream; it is a real possibility taking shape in China’s fields and ports.

👉 Read more: Biomethanol from Corn Straw in China: A Life-Cycle Insight

References

Wang, C., Wang, Z., Feng, M., Liu, J., Chang, Y., & Wang, Q. (2025). Assessing the triple-bottom-line impacts of crop straw-based bio-natural gas production in China: An input‒output-based hybrid LCA model. Energy. https://doi.org/10.1016/j.energy.2025.134789

Wang, S., Li, C., Hu, Y., Wang, H., Xu, G., Zhao, G., & Wang, S. (2024). Assessing the prospect of bio-methanol fuel in China from a life cycle perspective. Fuel. https://doi.org/10.1016/j.fuel.2023.130255

Charalambous, M., Negri, V., Kamm, V., & Guillén-Gosálbez, G. (2025). Onboard Carbon Capture for Circular Marine Fuels. ACS Sustainable Chemistry & Engineering, 13, 3919 – 3929. https://doi.org/10.1021/acssuschemeng.4c08354

Wang, S., Yin, C., Jiao, J., Yang, X., Shi, B., & Richel, A. (2022). StrawFeed model: An integrated model of straw feedstock supply chain for bioenergy in China. Resources, Conservation and Recycling. https://doi.org/10.1016/j.resconrec.2022.106439

Fang, Y., Zhang, S., Zhou, Z., Shi, W., & Xie, G. (2022). Sustainable development in China: Valuation of bioenergy potential and CO2 reduction from crop straw. Applied Energy. https://doi.org/10.1016/j.apenergy.2022.119439

Fan, A., Xiong, Y., Yang, L., Zhang, H., & He, Y. (2022). Carbon footprint model and low–carbon pathway of inland shipping based on micro–macro analysis. Energy. https://doi.org/10.1016/j.energy.2022.126150

Li, T., Wei, G., Liu, H., Zhu, Y., Lin, Y., & Han, Q. (2024). Comparative Assessment of the Environmental and Economic Performance of Two Straw Utilization Pathways in China. BioEnergy Research. https://doi.org/10.1007/s12155-024-10784-x

Yang, Y., Liang, S., Yang, Y., Xie, G., & Zhao, W. (2022). Spatial disparity of life-cycle greenhouse gas emissions from corn straw-based bioenergy production in China. Applied Energy. https://doi.org/10.1016/j.apenergy.2021.117854

Wang, D., Zhang, J., Chen, Q., Gu, Y., Chen, X., & Tang, Z. (2024). Reducing the lifecycle carbon emissions of rice straw-to-methanol for alternative marine fuel through self-generation and renewable electricity. Energy Conversion and Management. https://doi.org/10.1016/j.enconman.2024.119202

Hu, J., Lei, T., Wang, Z., Yan, X., Shi, X., Li, Z., He, X., & Zhang, Q. (2014). Economic, environmental and social assessment of briquette fuel from agricultural residues in China – A study on flat die briquetting using corn stalk. Energy, 64, 557-566. https://doi.org/10.1016/J.ENERGY.2013.10.028

Xu, X., Yang, Y., & Xiao, C. (2018). Energy balance and global warming potential of corn straw-based bioethanol in China from a life cycle perspective. International Journal of Green Energy, 15, 296 – 304. https://doi.org/10.1080/15435075.2017.1382361