Regional Biomass Supply Hubs: Business Potential & Funding Strategies

Biomass is becoming a key renewable energy source that can reduce reliance on fossil fuels and cut environmental impacts. While biomass use is common in rural areas, remote communities face unique challenges in adopting it. These include scattered suppliers, high transportation costs, and small-scale energy demand.

Financial benefits of the Biomass hubs in 2025 and Beyond

Market prices for bioenergy products (biofuel, biochar, electricity) have the largest impact on project profitability. For instance, biochar production had a mean NPV of $41.5 million, but profitability dropped sharply with price volatility (Campbell et al., 2018). This growth is driven by increasing environmental concerns, supportive government policies like subsidies and tax incentives, and the push for a circular economy that utilizes waste for energy. Biomass is seen as a way to provide dispatchable, reliable power and reduce greenhouse gas emissions, and is also being used in combined heat and power (CHP) systems and for co-firing with coal to reduce carbon footprints. While challenges like inconsistent feedstock supply and technological limitations exist, continuous innovation and a focus on sustainable sourcing are expected to propel the market forward, with a strong concentration and growth potential in North America, Europe, and especially the Asia-Pacific region.

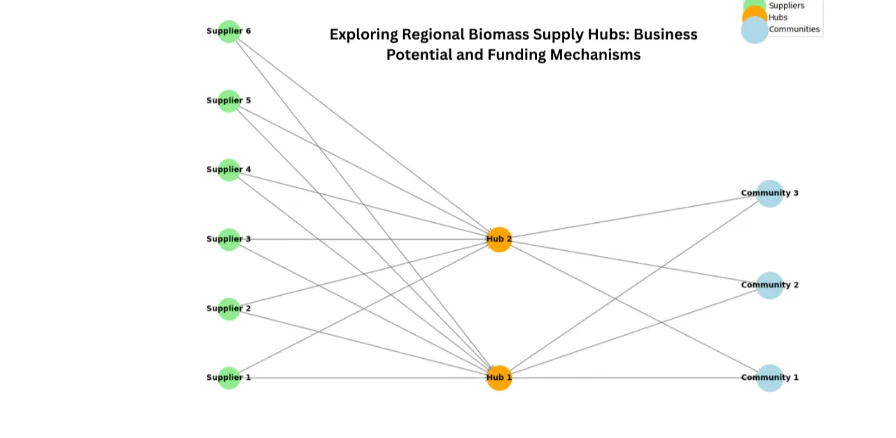

The solution lies in regional biomass supply hubs. With better coordination, supply chains can be more efficient, cost-effective, and sustainable.

The Anatomy of a Biomass Supply Chain

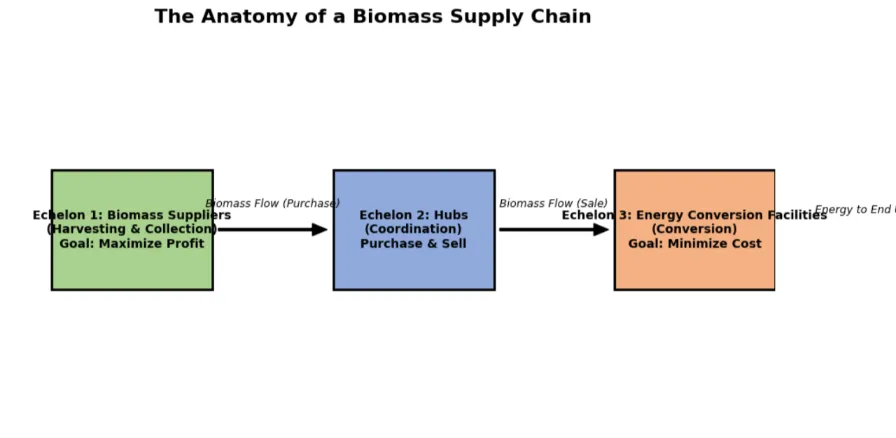

A biomass supply chain typically has three main layers:

The anatomy of a biomass supply chain is typically a three-echelon channel. The first echelon consists of biomass suppliers who are responsible for collecting and harvesting the biomass and then selling it to hubs. Their goal is to maximize their profit by determining the selling price of the biomass. The second echelon is made up of hubs, which coordinate the supply and demand sides of the chain, purchasing biomass from suppliers and selling it to energy conversion facilities. Finally, the third echelon includes the energy conversion facilities, which convert the biomass into energy, such as heat and electricity, for end users. These facilities aim to minimize the cost of energy production when deciding how much biomass to purchase and convert.

- Suppliers – Farmers, loggers, and other suppliers harvest and sell biomass.

- Hubs – Supply hubs play a crucial role by storing, managing, and linking suppliers with buyers.

- Energy Converters (Communities) – Facilities or communities that convert biomass into heat and electricity.

Each layer has its own costs, risks, and benefits. But when they work together strategically, the system becomes more efficient and reliable.

Why Strategic Coordination Matters

Without coordination, biomass projects in remote areas struggle with high costs and supply issues. Research shows that a game-theory approach (the Stackelberg model) helps explain how different players—suppliers, hubs, and communities—can cooperate.

Three leadership scenarios exist:

- Suppliers lead the chain

- Hubs lead the chain

- Communities lead the chain

In each case, the leader benefits most because they make decisions first. Two strategies make coordination possible:

- Quantity Discounts – Encourages bulk buying, lowering per-unit costs.

- Side Payments – Financial incentives from leaders to followers to keep cooperation stable.

Case Study: Lessons from Northern Canada

Remote communities in Northern Canada (Kangigsujuaq, Salluit, and Ivujivik) rely heavily on diesel. Since local biomass is unavailable, they must import pellets.

Based on the provided case study, remote communities in Northern Canada, such as Kangigsujuaq, Salluit, and Ivujivik, face the unique challenge of relying on imported diesel for energy due to the local unavailability of biomass. This dependency highlights the need for a coordinated biomass supply chain, even when the primary feedstock must be shipped from elsewhere. The study’s key finding is that while coordination and shared leadership benefit all participants in the supply chain, the most effective outcomes are achieved when the local communities themselves take the lead. This community-centric approach is crucial for successfully managing the logistics and economic viability of importing biomass pellets, ensuring the supply chain meets their specific needs and ultimately leads to better results.

Community-Led Supply Chains: Unlocking Business Potential

When communities act as leaders in the biomass supply chain, the outcomes are most cost-effective and sustainable.

Key benefits include:

- Lower Costs: Communities secure biomass at the cheapest rates, cutting energy costs.

- More Renewable Energy: Biomass becomes more competitive, increasing its share in the local energy mix.

- Stable Cooperation: Communities can provide side payments to hubs and suppliers, ensuring reliable long-term partnerships.

This leadership model creates the strongest business case for renewable energy projects in remote regions.

Funding Strategies for Biomass Hubs

To make biomass projects financially viable, communities can explore:

- Government Grants & Subsidies – Many countries offer renewable energy funding.

- Public-Private Partnerships – Shared investment reduces risks and builds stronger networks.

- Community Investment Models – Local ownership ensures commitment and long-term success.

- Carbon Credits & Green Financing – Additional revenue streams from sustainable practices.

Latest Funding Strategies and Financial Performance

Recent research highlights several effective funding strategies for biomass hubs:

- Bank Loans: Case studies show bank loans as a highly profitable funding option. For example, a 2024 Indonesian biomass project using bank loans achieved an NPV of Rp 8.5 billion, an IRR of 31%, and a payback period of 4 years, offering benefits like risk diversification, tax advantages, and quick fund disbursement .

- Green Finance: Green finance (GF) is increasingly accessible and supports sustainable innovation, but barriers remain, such as policy uncertainty, limited financial supplier involvement, and short-term financial instruments. Long-term, stable policy frameworks are essential to reduce perceived risks for investors 120.

- Public-Private Partnerships (PPP): In China, PPP models attract social capital, broaden financing methods, and diversify investment sources, but project profitability often depends on strong policy support and market stability .

- Government Grants and EU Funds: In the EU, regional and structural funds have covered 15–85% of project costs, with nearly half of projects receiving over 45% co-funding, enabling significant bioenergy infrastructure development .

Opportunity Websites and Resources

- EU Funding & Tenders Portal: https://ec.europa.eu/info/funding-tenders/opportunities/portal/

- Green Finance Platforms: Many countries have national green finance initiatives (e.g., Italy’s Green Economy on Capital Markets ).

- Development Banks: World Bank, Asian Development Bank, and regional banks offer biomass project funding.

- Local Government and PPP Platforms: Country-specific portals for PPP opportunities (e.g., China PPP Center).

Conclusion: The Future of Biomass in Remote Communities

Establishing regional biomass supply hubs is not just about logistics—it’s a strategic move for cost savings, energy security, and environmental sustainability.

By taking the lead, communities can build strong, efficient, and financially stable biomass supply chains. With the right funding strategies, this approach unlocks both business potential and long-term clean energy benefits, moving remote regions closer to a sustainable future.

Citations

Campbell, R., Anderson, N., Daugaard, D., & Naughton, H. (2018). Financial viability of biofuel and biochar production from forest biomass in the face of market price volatility and uncertainty. Applied Energy. https://doi.org/10.1016/J.APENERGY.2018.08.085.

Building Investor Confidence & De-risking Capital Investment in Advanced Biofuel Value Chains