Green Methanol Vehicles in China: Energy & Cost Analysis – Driving Towards a Sustainable Future?

China, the world’s largest automotive market, is actively pursuing alternative fuel technologies to fight air pollution and decrease its dependence on imported oil. One promising option is green methanol, a renewable liquid fuel made from sustainable sources like biomass or captured carbon dioxide along with renewable hydrogen. This analysis explores the energy effects and cost-effectiveness of green methanol vehicles in China. It looks at their potential role in the country’s move toward a cleaner transportation sector.

Green methanol vehicles are gaining attention in China as a promising pathway to reduce carbon emissions and enhance energy security. Unlike traditional methanol vehicles, which often rely on coal-derived methanol and have high emissions, green methanol is produced from renewable sources such as biomass or captured CO₂, offering significant environmental benefits.

Understanding Green Methanol:

Methanol (CH3OH), also known as wood alcohol, is a simple alcohol that can be used as a fuel. Traditional methanol production relies on fossil fuels like natural gas and coal, resulting in significant greenhouse gas emissions. Green methanol, however, offers a sustainable alternative by utilizing renewable feedstocks and energy sources throughout its production cycle.

Production Pathways for Green Methanol:

Several pathways exist for producing green methanol, each with its own energy and cost profile:

- Biomass Gasification: This process involves converting organic matter like agricultural waste, forestry residues, or dedicated energy crops into a syngas, which is then catalytically converted to methanol.

- Power-to-Methanol (PtM): This route utilizes renewable electricity to produce hydrogen through electrolysis of water. The hydrogen is then reacted with captured carbon dioxide (from industrial sources or direct air capture) to synthesize methanol.

- Biogas Reforming: Biogas, produced from anaerobic digestion of organic waste, can be reformed to produce syngas, which is subsequently converted to methanol.

Energy Analysis of Green Methanol Production:

The energy balance of green methanol production is crucial for evaluating its sustainability. While specific energy inputs vary depending on the chosen pathway and technology, the overall goal is to minimize fossil fuel consumption and maximize the use of renewable energy sources.

- Biomass Gasification: This method can be energy-efficient if sustainable biomass sources are readily available and transportation distances are minimized. However, the energy required for feedstock cultivation, harvesting, and pre-processing needs to be considered.

- Power-to-Methanol (PtM): PtM is inherently energy-intensive due to the electrolysis of water and the subsequent synthesis steps. The overall efficiency of the process depends heavily on the efficiency of electrolyzers and the availability of low-cost renewable electricity.

- Biogas Reforming: This pathway can offer a relatively energy-efficient route if biogas is produced sustainably and the reforming process is optimized.

Energy Density and Vehicle Efficiency:

Methanol has a lower energy density compared to gasoline or diesel, meaning a vehicle would need to carry a larger volume of methanol to achieve the same driving range. This can impact vehicle design and packaging. However, methanol burns cleaner than conventional fuels, potentially leading to lower emissions of particulate matter, nitrogen oxides (NOx), and sulfur oxides (SOx).

Dedicated methanol vehicles or flex-fuel vehicles capable of running on both gasoline and methanol are necessary for widespread adoption. The efficiency of methanol-fueled internal combustion engines (ICEs) is comparable to gasoline engines, although optimization for methanol can further improve performance.

Cost Analysis of Green Methanol Vehicles in China:

The economic viability of green methanol vehicles hinges on several factors, including the cost of green methanol production, vehicle manufacturing costs, and fuel infrastructure development.

Cost of Green Methanol Production:

Currently, green methanol production costs are generally higher than those of conventional methanol due to the higher cost of renewable energy and the relatively nascent stage of green methanol production technologies. However, costs are expected to decline as renewable energy prices continue to fall and production scales up.

- Feedstock Costs: For biomass-based methanol, the cost and availability of sustainable biomass feedstocks are critical. For PtM, the cost of renewable electricity is the dominant factor.

- Capital Costs: Building and operating green methanol production facilities require significant upfront investment. Technological advancements and economies of scale will be crucial for reducing capital costs.

- Operating Costs: These include energy consumption, catalyst replacement, and maintenance. Optimizing production processes can help minimize operating costs.

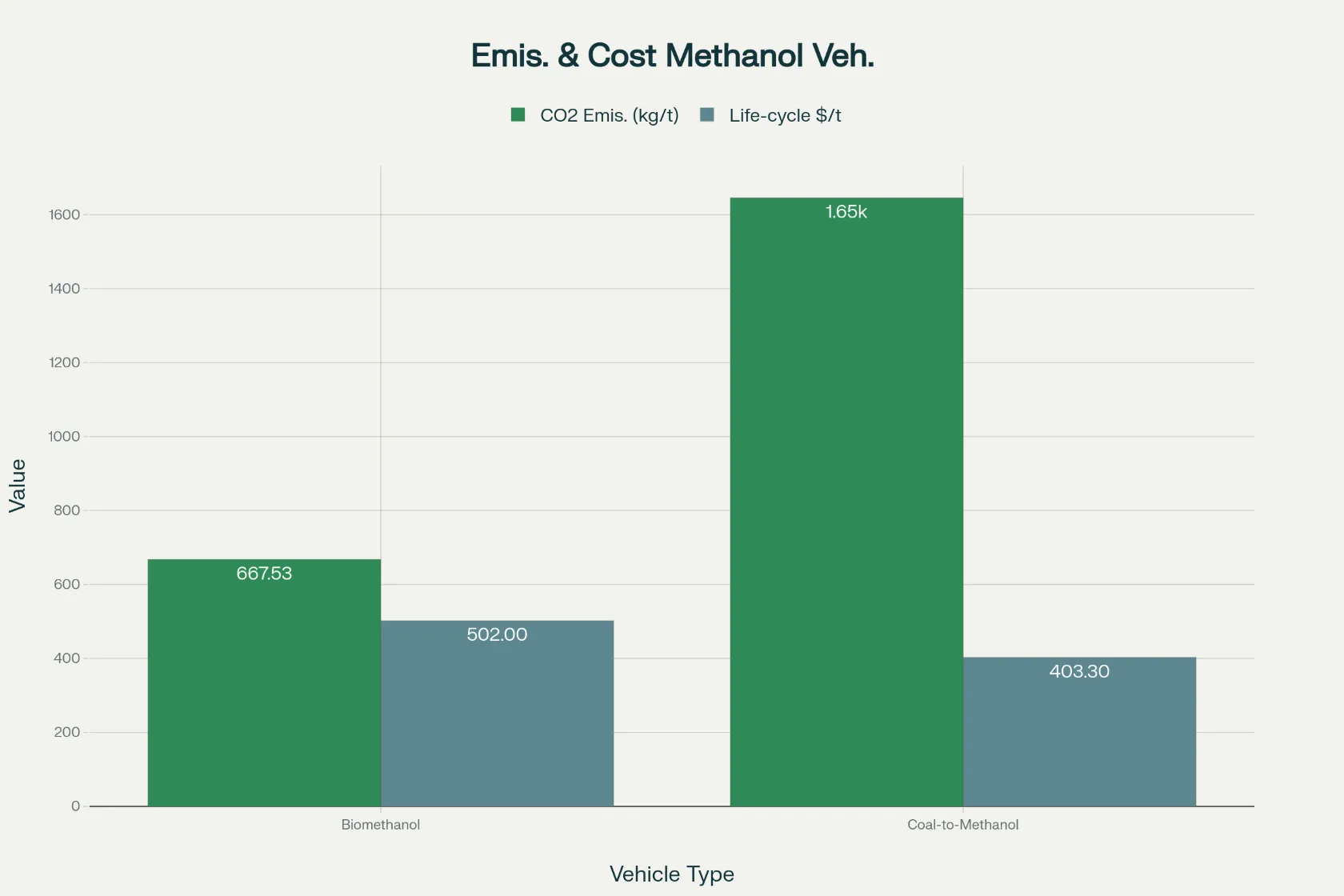

The image presents a comparative analysis of green methanol vehicles in China, focusing on biomethanol versus coal-to-methanol vehicles. It highlights the significant environmental advantage of biomethanol vehicles, which achieve a 59% reduction in CO₂ emissions (667.53 kg/ton) compared to coal-to-methanol vehicles (1,645.5 kg/ton). Despite having a higher life-cycle cost—about $502 per ton versus roughly $403 for coal-to-methanol—biomethanol vehicles offer substantial emissions savings, underscoring their potential as a sustainable transport option. The data showcases how biomethanol vehicles currently balance higher costs with notable environmental benefits, emphasizing the importance of policy support and technological advancements to enhance economic competitiveness and accelerate adoption in China’s transport sector (Li et al., 2022).

Biomass-to-methanol vehicles (biomethanol) demonstrate the best overall performance, ranking highest in comprehensive evaluations of energy use, emissions, and cost. Biomethanol vehicles can reduce CO₂ emissions by up to 59% compared to coal-to-methanol vehicles and by 24% compared to gasoline vehicles, with minimal additional energy and water consumption . CO₂-to-methanol vehicles also offer emission reductions but currently face high energy consumption and production costs

Vehicle Manufacturing Costs:

Producing methanol-specific or flex-fuel vehicles may involve some additional manufacturing costs compared to conventional gasoline or diesel vehicles due to modifications to the fuel system and engine components to handle methanol’s properties. However, these costs are expected to decrease with increasing production volumes and technological maturity.

Fuel Infrastructure Costs:

Establishing a refueling infrastructure for methanol vehicles is essential for their widespread adoption. This includes storage tanks at production facilities, transportation pipelines or tankers, and refueling stations. The cost of building this infrastructure can be substantial, but it can be phased in strategically, focusing initially on specific regions or applications.

Biomethanol vehicles are economically viable, with life-cycle costs only moderately higher than coal-based methanol but with much greater environmental benefits . The cost of green methanol production is influenced by technology maturity, renewable energy prices, and policy incentives. For CO₂-to-methanol, significant cost reductions in renewable hydrogen and process improvements are needed for competitiveness

A clear, table summarizing key vehicle manufacturing costs: battery pack costs decreasing from $1,000/kWh in 2007 to $410/kWh in 2014, with projections of $100/kWh by 2025–2030; material costs showing steel as a baseline at 1.0 and aluminum at 0.85 relative cost; indirect manufacturing cost multipliers ranging from 1.05 to 1.45 times direct costs, representing R&D, overhead, and marketing expenses (Burd et al., 2020).”

Government Policies and Incentives:

The Chinese government plays a crucial role in shaping the adoption of alternative fuels. Supportive policies, such as subsidies for green methanol production and vehicle purchases, tax incentives, and mandates for the use of cleaner fuels in certain sectors, can significantly accelerate the deployment of green methanol vehicles.

Experts recommend dynamic policy support, including scaling up biomethanol vehicles where local conditions allow and advancing CO₂-to-methanol technology for future deployment. Preferential policies and incentives are crucial for integrating green methanol vehicles into China’s new energy vehicle strategy

Potential Applications of Green Methanol Vehicles in China:

Green methanol can potentially power various vehicle segments in China:

- Heavy-Duty Trucks and Buses: Methanol’s higher density compared to compressed natural gas (CNG) and its suitability for combustion engines make it an attractive alternative fuel for long-haul transportation and public transit.

- Passenger Cars: Flex-fuel or dedicated methanol cars can offer a lower-emission alternative to gasoline vehicles, particularly in regions with high air pollution.

- Marine and Rail Transport: Green methanol can also be used as a fuel for ships and trains, contributing to decarbonization efforts in these sectors.

Challenges and Opportunities:

Despite its potential, the widespread adoption of green methanol vehicles in China faces several challenges:

- Production Scalability: Scaling up green methanol production to meet the demands of the transportation sector requires significant investment and technological advancements.

- Infrastructure Development: Building a robust and cost-effective methanol refueling infrastructure is a major undertaking.

- Public Awareness and Acceptance: Raising public awareness about the benefits of green methanol and ensuring consumer acceptance are crucial for market penetration.

- Competition from Other Alternative Fuels: Battery electric vehicles (BEVs) and hydrogen fuel cell vehicles (FCEVs) are also being actively promoted in China, creating competition for green methanol.

However, there are also significant opportunities:

Conclusion:

Green methanol offers a promising way to cut emissions in China’s transportation sector. There are challenges, such as high production costs, the need for better infrastructure, and competition from other alternative fuels. However, the benefits include lower emissions, increased energy security, and new economic opportunities. With ongoing improvements in technology, supportive government policies, and smart investments, green methanol vehicles could be key in moving China toward a more sustainable and eco-friendly transportation future. An energy and cost analysis shows that while initial costs may be higher, the long-term environmental and social benefits make green methanol worth more research, development, and deployment in China. Widespread adoption will need teamwork from governments, industry leaders, and consumers.

CITATIONS

Assessing the prospect of deploying green methanol vehicles in China from energy, environmental and economic perspectives. Energy. https://doi.org/10.1016/j.energy.2022.125967.

Improvements in electric vehicle battery technology influence vehicle lightweighting and material substitution decisions. Applied Energy, 116269. https://doi.org/10.1016/j.apenergy.2020.116269.

checkout also

Green Methanol Vehicles in China & Biomethanol’s Role