Beyond Fossil Feedstock: Biomethanol’s Crucial Role in Decarbonizing the Chemical Industry

As the global chemical industry faces mounting pressure to reduce carbon emissions and transition from fossil fuels, biomethanol has emerged as a game-changing solution. Derived from renewable feedstocks such as organic waste and agricultural residues, biomethanol offers a sustainable, low-carbon alternative to traditional fossil-based methanol. This shift not only supports the circular economy but also addresses critical issues like land use and food security, positioning biomethanol as a cornerstone in the decarbonization of the chemical sector.

In this comprehensive blog, we explore the production processes, environmental benefits, industrial applications, and future outlook of biomethanol, highlighting why it is indispensable for a sustainable chemical industry.

What is Biomethanol?

Biomethanol is chemically identical to conventional methanol (CH3OH) but is produced from renewable biomass rather than fossil fuels. It is a versatile chemical used extensively as a feedstock for producing formaldehyde, acetic acid, olefins, and other industrial chemicals. Additionally, biomethanol serves as a clean-burning fuel and a precursor for biofuels like sustainable aviation fuel (SAF) and bio-gasoline.

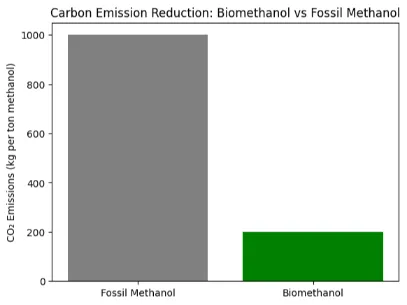

Unlike fossil methanol, biomethanol’s carbon content originates from atmospheric CO₂ captured by plants during growth, making its lifecycle carbon footprint significantly lower. This renewable methanol supports a circular economy by converting waste biomass into valuable products, reducing greenhouse gas (GHG) emissions, and minimizing environmental impact.

How is Biomethanol Produced?

Biomass Gasification and Syngas Conversion

One of the most advanced routes to produce biomethanol is through gasification of biomass or organic waste. This process converts solid biomass into synthesis gas (syngas), a mixture of carbon monoxide, hydrogen, and carbon dioxide. The syngas is then catalytically converted into high-purity biomethanol using advanced methanol synthesis technology.

Johnson Matthey, a leader in this field, has developed a robust biomass-to-methanol process that maximizes conversion efficiency and tolerates impurities present in biomass-derived syngas. Their technology can also integrate green hydrogen to boost biomethanol yields and further reduce carbon intensity.

Integration with Pulp Mills and Waste Streams

Another promising production model involves integrating biomethanol synthesis with existing industrial processes. For example, Veolia’s biorefinery in Finland produces CO₂-neutral biomethanol by refining crude sulfate methanol derived from pulp production. This approach leverages the large availability of biomass residues in pulp mills and could be replicated globally, unlocking millions of tons of sustainable feedstock.

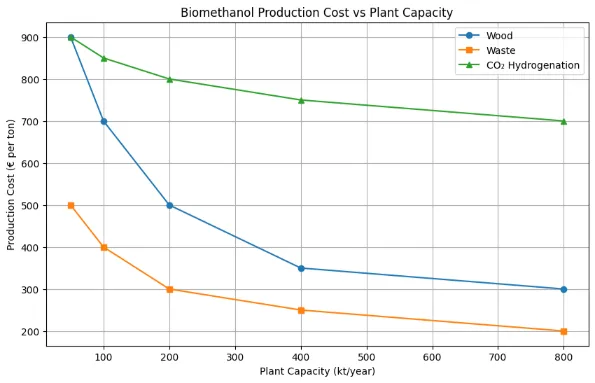

Emerging Technologies: Direct CO₂ Hydrogenation

Innovative methods are being explored to produce biomethanol by directly hydrogenating CO₂ with green hydrogen. While currently less cost-competitive than steam reforming, this approach holds promise for decentralized, small-scale production facilities, especially when paired with cheap renewable electricity.

Why Biomethanol is Vital for Decarbonizing the Chemical Industry

- Significant Carbon Emission Reductions

Biomethanol production from waste biomass or biogas can drastically cut greenhouse gas emissions compared to fossil methanol. Using renewable feedstocks ensures that the carbon released during methanol use is balanced by the carbon absorbed during biomass growth, achieving near carbon neutrality. - Supports Circular Economy and Waste Valorization

By converting organic waste streams—such as municipal solid waste, agricultural residues, and industrial by-products—into valuable methanol, biomethanol production reduces landfill use and methane emissions from waste decomposition. This closes material loops and promotes sustainable resource use. - Enables Decarbonization of Hard-to-Abate Sectors

Methanol is a key feedstock for chemicals and an emerging fuel for sectors difficult to electrify, including maritime shipping and aviation. Biomethanol as a marine fuel can reduce shipping emissions substantially, while its derivatives serve as building blocks for biofuels like SAF, aiding the decarbonization of air transport. - Enhances Energy Security

Local biomethanol production reduces dependency on fossil fuel imports and volatile global markets. Industrial symbiosis models, such as pulp mill integration, enable regional economies to leverage existing biomass resources for sustainable chemical feedstock production.

Industrial Applications of Biomethanol

- Chemical Feedstock: Biomethanol is used to manufacture formaldehyde, acetic acid, olefins, and other intermediates essential for producing plastics, paints, adhesives, and textiles.

- Fuel and Fuel Additive: It serves as a clean-burning fuel in internal combustion engines, a marine fuel alternative, and a precursor for biofuels such as biodiesel and methanol-to-gasoline (MTG).

- Energy Carrier: Biomethanol can store and transport renewable energy, especially when produced via power-to-X routes combining green hydrogen and CO₂.

Challenges in Biomethanol Adoption

Feedstock Availability and Quality

Scaling biomethanol production depends on a consistent supply of sustainable biomass feedstock. Variability in feedstock composition and availability can affect process efficiency and economics.

Cost Competitiveness

Currently, biomethanol production is more expensive than fossil-based methanol due to feedstock costs and technological maturity. However, innovations like chemical looping gasification and membrane reactors (e.g., the EU-funded Bio-MeGaFuel project) aim to reduce costs and improve scalability.

Technological Maturity

While gasification and steam reforming technologies are well-established, emerging routes such as direct CO₂ hydrogenation require further development to achieve industrial scale and cost-effectiveness.

The Future of Biomethanol in a Sustainable Chemical Industry

The transition to biomethanol is accelerating, driven by stringent environmental regulations, corporate sustainability commitments, and technological breakthroughs. Collaborative efforts between industry leaders, research institutions, and policymakers are crucial to:

- Expand biomass supply chains and optimize feedstock logistics.

- Scale up innovative production technologies that reduce costs and increase efficiency.

- Develop integrated biorefineries combining biomethanol with green hydrogen and carbon capture.

- Foster market demand through incentives, carbon pricing, and green procurement policies.

The blend of biomethanol and e-methanol (produced from renewable electricity and CO₂) will likely form the backbone of a defossilized methanol supply chain, enabling the chemical industry to meet ambitious climate targets.

Conclusion

Biomethanol stands at the forefront of the chemical industry’s decarbonization journey. Its ability to transform waste biomass into a versatile, low-carbon feedstock and fuel underscores its pivotal role in achieving a sustainable, circular economy. As production technologies mature and costs decline, biomethanol will become indispensable for reducing greenhouse gas emissions across chemicals, fuels, and hard-to-abate sectors such as shipping and aviation.

Transitioning beyond fossil feedstocks to biomethanol is not just an environmental imperative—it is a strategic opportunity to innovate, create resilient supply chains, and lead the chemical industry into a greener future.

Want to Learn More About Sustainable Chemistry Solutions?

Subscribe to our newsletter for the latest insights on renewable feedstocks, green chemistry innovations, and industry decarbonization strategies.

Subscribe NowBiofuels PK

Sustainable Energy Solutions for a Greener Future

Heat Wave Warnings vs Carbon Revenue

Exploring the balance between climate change warnings and the economic opportunities in carbon reduction technologies.

Read ArticleHeat Wave Warnings and Biofuels

How biofuels can play a crucial role in mitigating the effects of increasing heat waves and climate change.

Read ArticleCooks Are Experts

Discover how culinary experts are contributing to sustainable practices in the biofuels industry.

Read ArticleHow to Make Biochar

A step-by-step guide to producing biochar, an excellent soil amendment and carbon sequestration method.

Read Article