A Case Study of the Expedition of Biomass Energy

Expedition of Biomass Energy

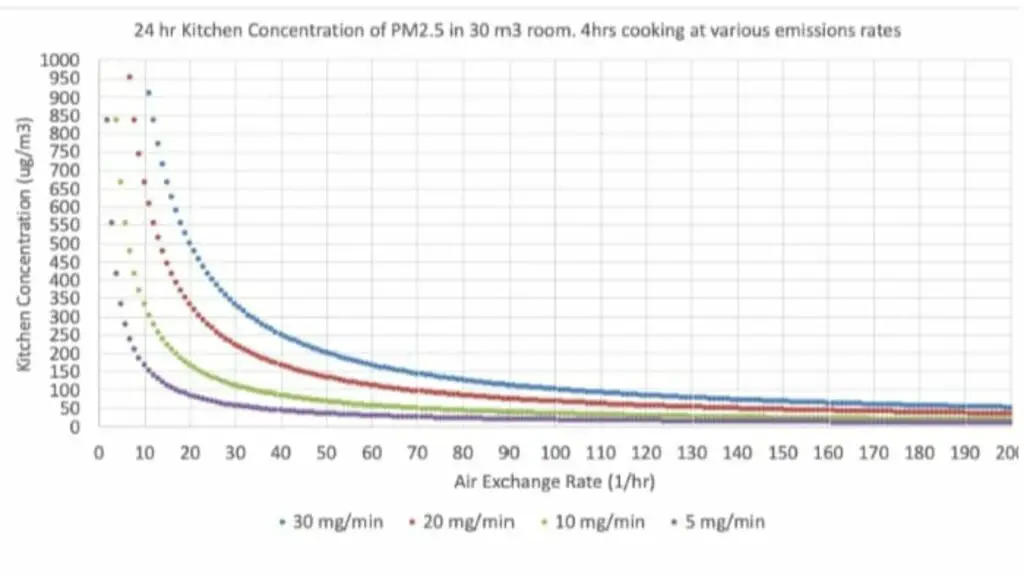

The Expedition of biomass energy such as composite briquettes of sawdust becomes a good source of renewable energy for household cooking. This product contains so many benefits. A broad biomass range includes wood waste from forest-based industries crop residues food and paper industries residue municipal solid waste. it can be utilized in different energy types such as heat electricity combined heat& power and some other types of bioenergy. Biomass is referred to all biological matters including all kinds of substances originating from living organisms and it’s the 3rd largest energy source of the world. Since understanding the application and viability of the briquettes. The author started working five years ago. The author starts by simply making briquettes in a pot by mixing the char with starch(binding agent). Then used later these briquettes to fry an egg for breakfast. In this blog Author shares, it entire effort to show the world, especially developing countries. in this Blog/article a case study of the expedition of biomass energy short brief is discussed. By implementing more or less you will become part of the movement to fight against climate change & save the world before it’s too late.

Collection of Raw material

The input material for the production of quality briquettes was collected from the three main markets of Bahawalpur. To gather the data for the average production of the briquettes. 07- Days field visit and collection of waste performed. No statistical analysis was made before it for the collection and usage of this fraction of waste for recycled and reused sustainably. There are 3 main points used for the analysis of the physical composition, type, and generation of industrial waste.

1) By using primary data to make an empirical approachability

2) Questionnaire

3) Using controlled and monitored data from existing waste management

system.

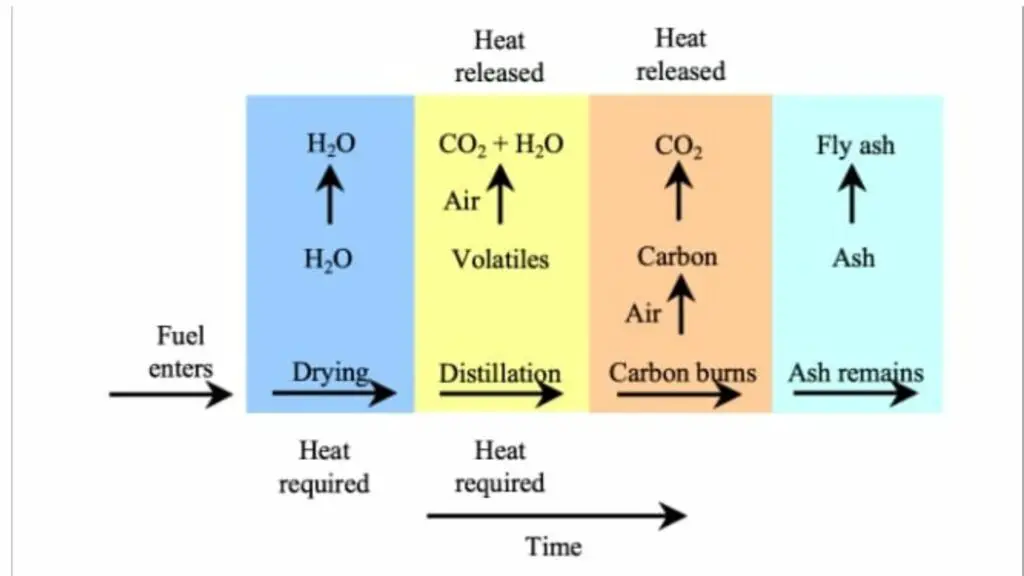

Converting raw material into Biomass energy

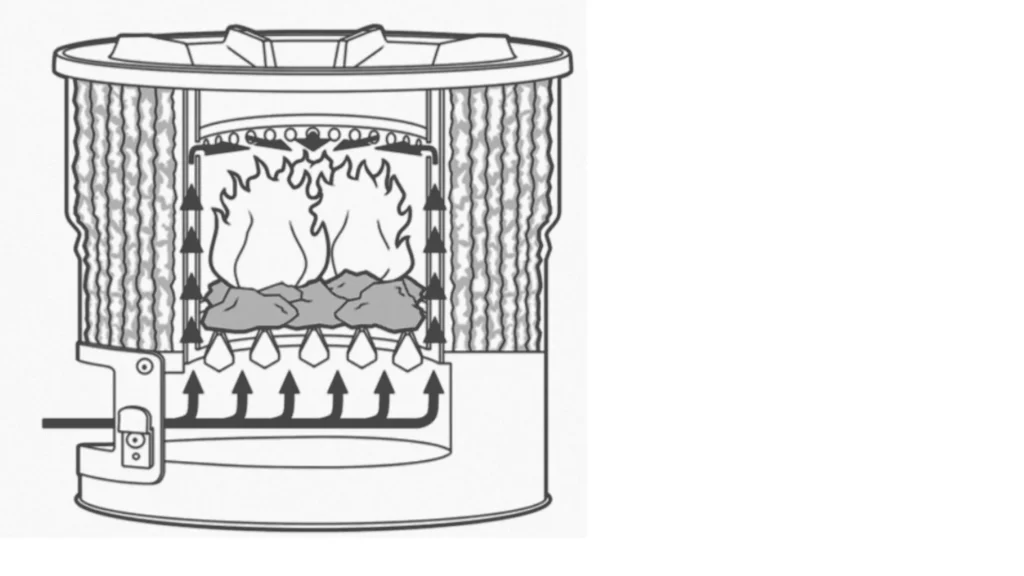

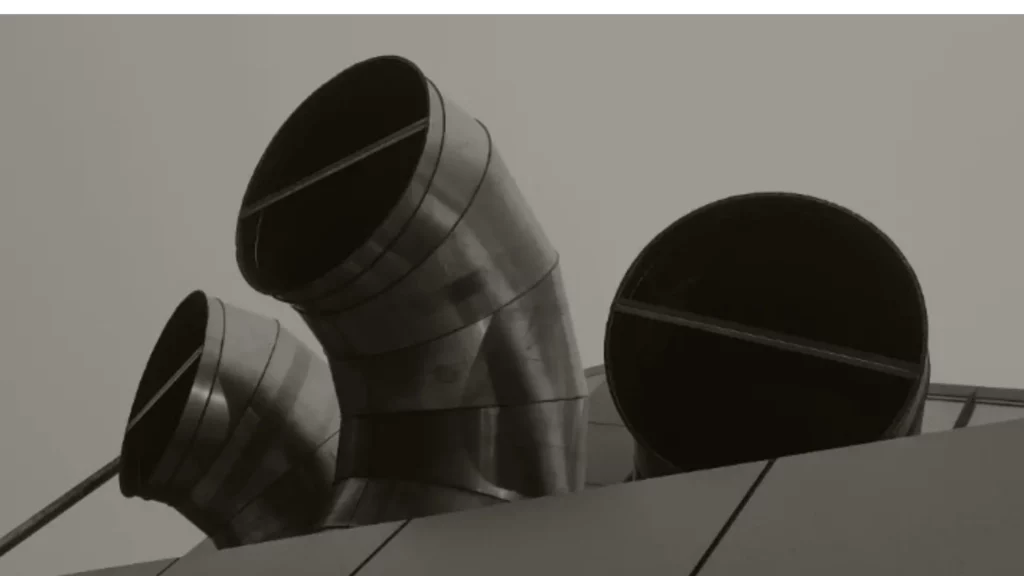

The collected sawdust was spread and cleaned from metallic scrap and other contaminations with the help of sieves and magnets. Thereafter the raw material is loaded into the pyrolyzer. The sawdust ignited with the help of match stick and then covered from the top. The small holes in the drum control the combustion air. The size of the holes in the drum reduces the excess amount of oxygen thus causing slow carbonization in the drum. The whole process was referred to the slow pyrolysis. The process takes 7 to 8 hrs up to the complete carbonization of the feed.

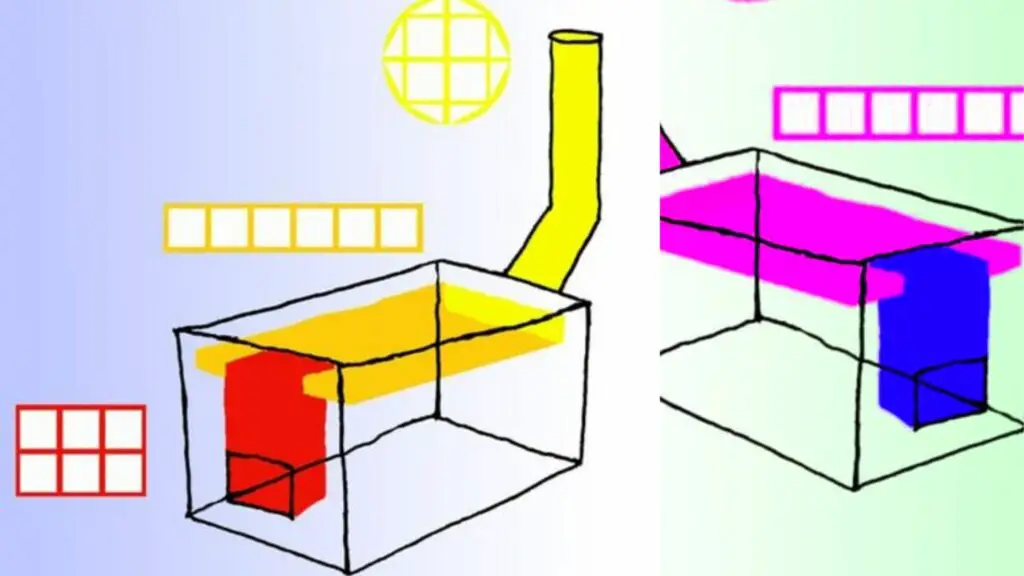

Making equipment for Expedition of biomass energy

The collected waste from different furniture markets gathered and by using briquette machine. The charcoal briquettes were produced. The cylindrical shape of briquettes made them easy to handle, store and use. The

briquettes were packed in the 40kg polyethylene bag for storage purposes. The shape of the briquettes gave them a good shutter index value. The amount of sawdust used and no of briquettes produced was a cost-effective element of the study. The biomass waste can be used sustainably to fulfilling the all postulates of the integrated solid waste management.

Briquette Machine (Expedition of biomass energy)

The machine was modified in the local wood workshop with main parts main frame which was made of wood, molding unit, safety block and 2 hp motor. The prepared feed made from char and starch as a binding agent is the form of lump so the meat mince machine modified as it was highly suitable and easily locally available for the production of the briquettes. As the char and starch mixed together became the agglomeration form so the modified machine with the 1 HP motor can easily operate to form the cylindrical-shaped charcoal briquettes.

Safety block

The safety aspect of the machine is considered. To meet the safety for workers a block of woods is installed at backside of the motor where rotary wheel and extruder were connected. The wooden blocks were arranged in that manner the machine become easy to open for maintenance and will protect the operators from sudden accidental injuries. The main cause of injuries was mainly occurred at rotary wheel sections due to human errors or mechanical troubleshooting.

Evaluation of the Potential of Briquettes

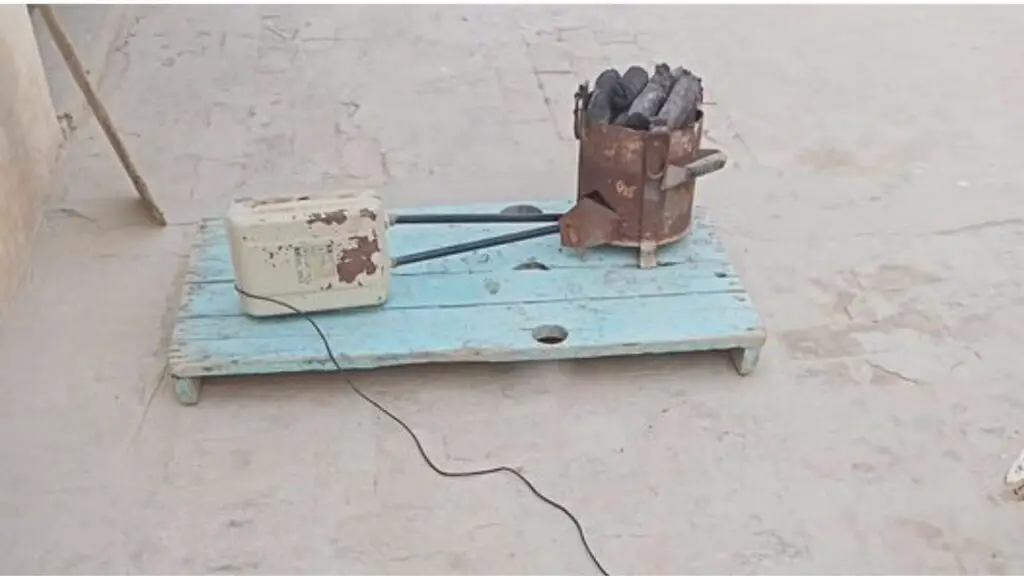

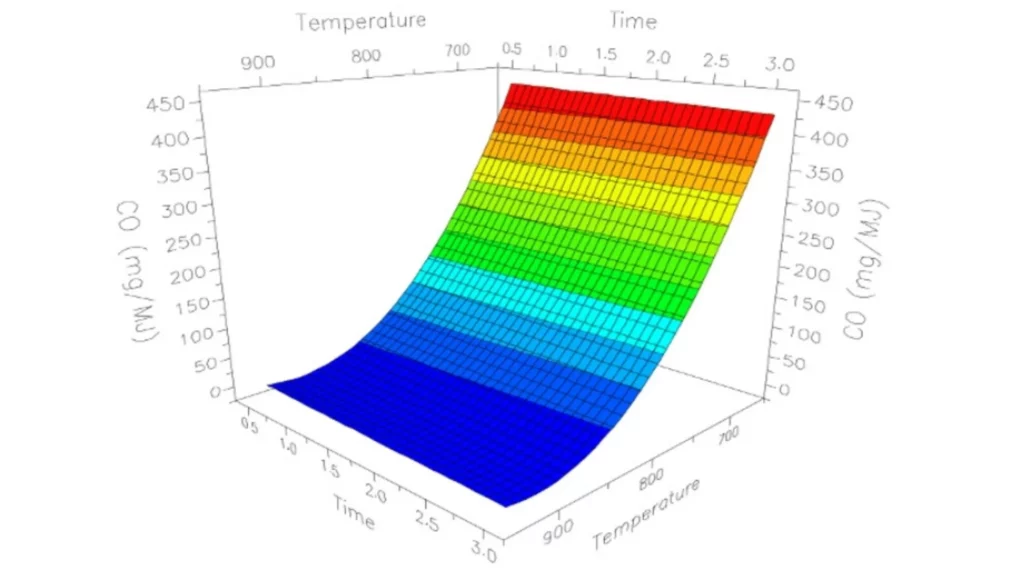

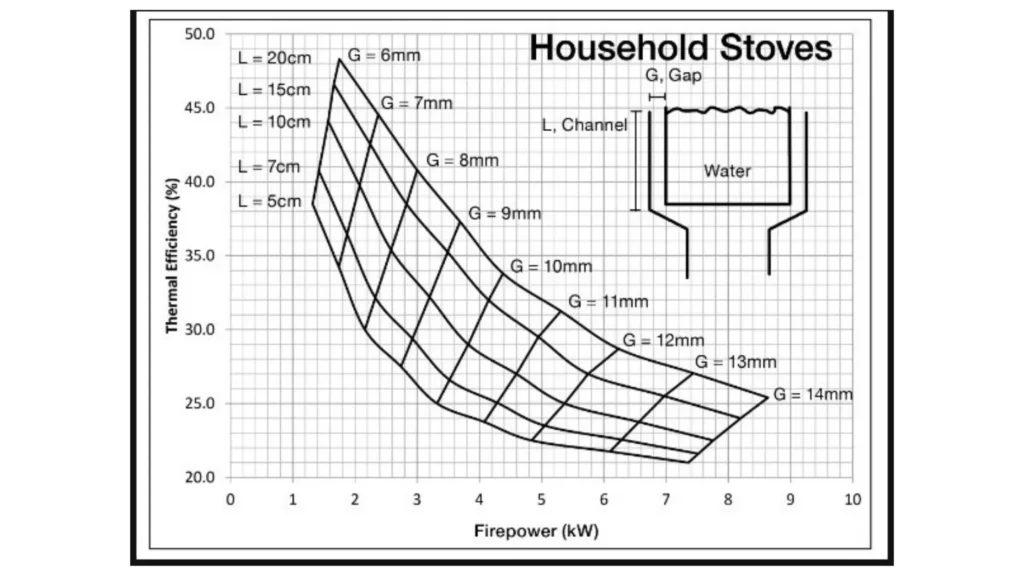

The evaluation of bioenergy refers to the calorific value of the product and its sustainable household usage for the cooking and space heating is the main aspect of the utilization of this specific waste into charcoal briquettes. The next phase of the study, the household usage of these briquettes and the burning rate of the charcoal briquettes shows the bioenergy potential. The burning rate test was performed on 01-liter water boiling and 01 egg frying. The

time and Number of briquettes used in boiling and frying were noted. The rate of burning leads to the find the applicability of these briquettes in household usage and also the economic aspect of the briquette production against the traditional used wood and charcoal for cooking and space heating, especially in rural areas where people don’t have access of natural gas and cheaper fuels. The burning rate test was performed on the iron stove in which briquettes were placed and ignited with match sticks. The number of briquettes and time taken to boil the water noted.

Promotion of Briquetting Technique

This success leads author to promote and develop a strong community, which can also promote and adopt this sustainable technique in different regions of world as well as in Pakistan. The First priority is to explode the expedition of biomass energy. the As country has a frail economy so government does not really admire or support such sustainable development. so Author decide to promote and implement this whole success story on his own. The best way to implement this is through social media and website making. so Author made a Website named biofuelspk.com. The making of a website is a difficult task but By using WordPress for the main interface. The next step is Webhosting for the best Webhosting experience Author used Vultr.com. In this site, many articles have been written for the purpose of promoting bioenergy, biofuels and other renewable sources. All the blogs/articles have different kinds of techniques that are sustainable and address benefits of both climate change and global warming issues. The main Blogs/articles named the nexus of renewables to energy impediment , Epic tips and tweaks for indoor sustainability There are so many other platforms which author used from social media you may try to get more Youtube channel, Biofuels,Bioenergy Potential, wealth of waste. In starting moment or struggle for become the part of the moment one’s should understand the power and applications of social media. without it any effort or struggle in any form movement will be ruined because it is the best opportunity to share your work with the world.

Conclusions

As the world’s environment going critical day by day. it is our duty to show some part of the moment for their inhaling and betterment. As time passed it is getting worse. so above mentioned case study is a little part of the entire world that the world actually doing for many years. This blog/ article a case study of the expedition of biomass energy will give you the basic guideline for how to start acting from your home. All the techniques and tips are performed by Author highly efficient and cheap to adopt in any kind of dwelling. watch visit the given links and become a part of the World’s emerging and leading problem.

For insights into China’s low-cost, high-gain approach to biomethanol production, check out our detailed article: Fueling Profits: The Chinese Model for Low-Cost, High-Gains Biomethanol .

A Case Study of the Expedition of Biomass Energy Read More »