Introduction

In this study, a few best practices and tips are shown that would help to retain Indoor Sustainability. This is one of the serious issues that the world still facing due to the lack of socio-economic resilience. This type of pollution refers to dust, dirt, or gases in the air inside buildings. Pollutants could be harmful to breathing. Indoor air pollution has been linked to lung diseases like asthma and lung cancer.

Indoor Sustainability

It refers to the air quality within and around buildings and house’s best Products. Especially as it relates to the health and comfort of occupants. Understanding and controlling common pollutants indoors can help reduce your risk of indoor health concerns. Health effects from indoor air pollutants may be shown soon after exposure or, possibly, years later.

Sneak peak of different pollutants

Following are a few sources that are major causes of indoor Pollution

- Fuel-burning combustion appliances

- Tobacco products

- Products for household cleaning and maintenance, personal care, or hobbies

- Central heating and cooling systems and humidification devices

- Excess moisture

- Outdoor sources such as:

- Pesticides

- Outdoor air pollution.

Tips and tweaks for Indoor Sustainability

Here author suggested research-based tips and tweaks to reduce indoor Pollution. These important implications will enhance the awareness to people in the world to understand and also to obstruct the hazardous effects of indoor pollution.

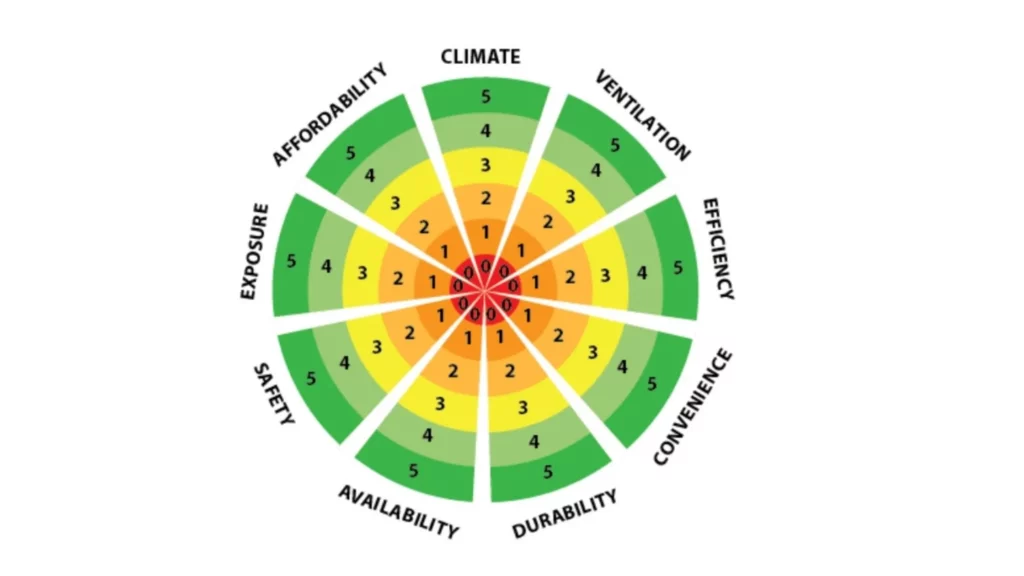

1– The best formula to evaluate environment vs cooking is a circular chart that helps to evaluate.

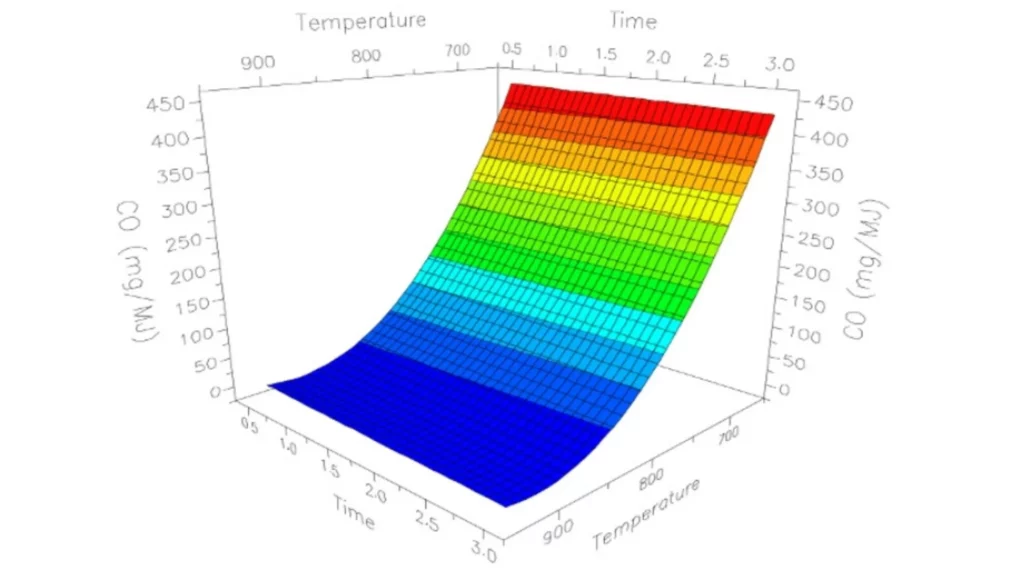

2– Experiments have shown that elevated temperatures shorten the combustion time for CO and PM 2.5. The following graph shows how the slight implementation gives the best results in understanding Time vs Temperature.

3-If the primary air supplied to a charcoal fire in stoves is reduced close to zero, the fuel will still keep burning. When the air supply is increased, the firepower will also increase.

4– Burning off the volatile compounds in wood consumes and wastes between 50% and 80% of the energy!

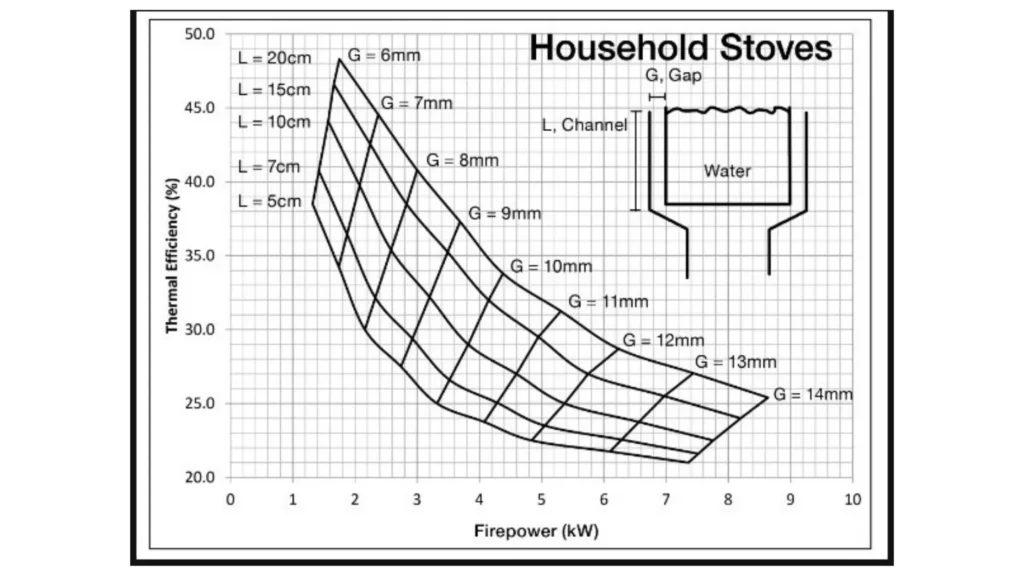

5– Hot, fast-flowing gasses transfer heat most efficiently. This is the chart for determining the thermal efficiency of the Biomass stove. This is also Applicable for the Household stoves.

6– The temperature of the hot gas above the wood is typically around 1100ºC. As the volatiles rise, they react with other volatile molecules forming soot and smoke and simultaneously burning as they mix with oxygen. Some 213 different compounds have so far been identified among these volatiles. If a cold object, such as a pot is placed close to the fire. It will cool and stop the combustion of some of these volatiles, leaving a thick black smoke.”

7. The clean-burning of Biomass consists of a few steps listed below

- The stove body and interior (including the combustion chamber) are low mass and insulative. The heat from the fire goes into the cooking process and is not diverted into the stove.

- The heat transfer efficiency is close to optimal resulting in over 40% thermal efficiency. One successful technique is to combine moderate firepower (2.5kW) with very small channel gaps (6mm) around the pot. Burning fewer wood results in fewer emissions.

- Emissions are reduced by increasing combustion efficiency. An appropriate amount of wood gas is made. The rate of reactions is controlled by adjusting the primary air or by metering the fuel.

- A zone of mixing of air, gases, smoke, and flame is created using jets of secondary air. The jets of secondary air can be powered by natural draft in a Top Lit Up Draft stove or by forced draft in both Rocket and TLUD stoves.

- The amount of flame,air,and wood gas entering the zone of mixing is adjusted until close to optimal combustion efficiency is obtained. Emissions in the exhaust stream can be further reduced with a catalyst. Removing the emissions from the living space in a chimney is mandatory comply with new WHO guidelines.

- The sixth step is the last and ultimate step. The prototype stove moves through an iterative development process by testing one change at a time under the emissions hood. The Water Boiling Test and the Controlled Cooking Test are both used to evolve a stove that is clean burning, fuel efficient, and cooks as well or better than the local model. The cooking function of the stove is designed by local users. The market viability of the product is determined by field testing involving stakeholders such as distributors, manufacturers, funders, consumers, etc. Market testing precedes and informs manufacturing.

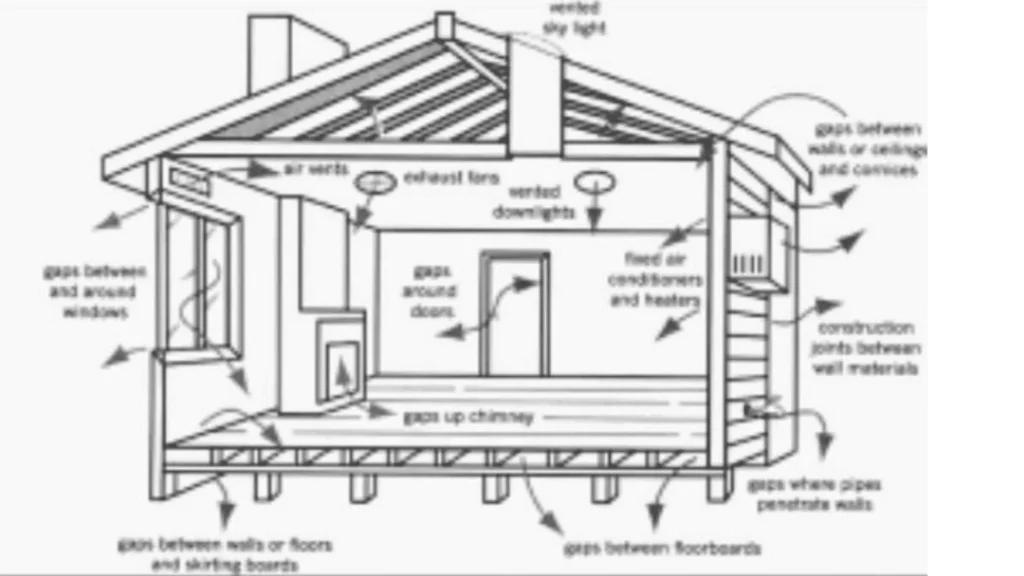

8– In-house Cooking the World Health Organization Indoor Air Guidelines figure that 25% of the total emissions going up a chimney end up inside the house because stoves and chimneys are leaking that much into the room air.

9– There are a number of methods to reduce personal exposure to household air pollution. it is associated with using biomass fuel for the daily cooking and heating taking place in nearly 40% of global households. These most commonly include

- Increasing ventilation rates,

- Installing a chimney

- The use of cleaner fuels and cook stoves.

10– Open fires made with moister wood and operated with less protection from the wind can score as low as 5%. The operator and the conditions of use largely determine the effectiveness of the operation. Stoves have to be tested with careful repetition in order to achieve statistical confidence in the results. Because there are so many differences between laboratory and field results, it is difficult to use the results of laboratory testing to predict exactly how stoves will perform in the real world.

11– Emissions reduced By filters, When cookstoves are operated inside an enclosure from which smoke is pulled through an inexpensive furnace filter before exiting to the outside, the personal exposure levels, room concentrations, and external pollution are reduced.

12– Ventilation can be part of, or a primary intervention strategy Stove performance. The usage must be considered together, as lower performing stoves can result in similar or greater fuel savings than a higher performing stove. If the lower performing stove has considerably higher displacement of the baseline stove.“There are multiple performance-usage scenarios for achieving modest indoor air quality improvements.”A systematic laboratory study showed that ventilation can reduce indoor concentrations of PM2.5 by as much as 60%. Also, median indoor PM2.5 concentrations were half as much for those cooking outdoors compared to indoors.

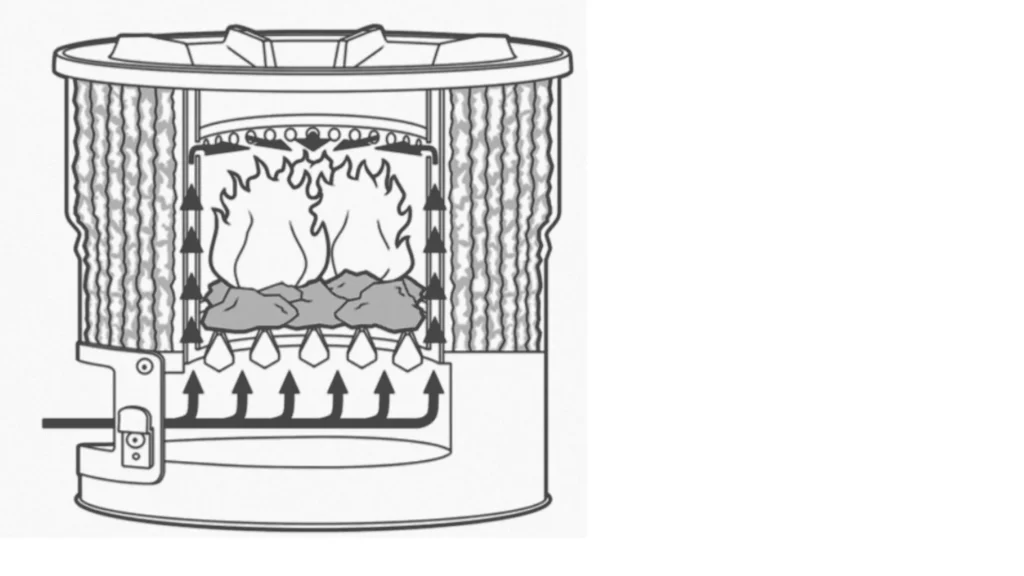

13. Combustion pattern in cooking stoves: In each case, the same principle applies: All the wood gas must go into the hot flames and Be well mixed there with air. For a long enough time for complete combustion to occur.

14. Size the combustion chamber for charcoal Briquettes stoves: Whatever fuel is loaded into the stove will be burned at a rate proportional to the amount of air made available to it. In most cases, more fuel loaded means more firepower because there is always excess air. The fuel is exposed to the air above it! When cooking small amounts of food, when not much power is required, load a small amount of fuel into the stove, or use a stove with a small combustion chamber. For cooking lots of food at once, use a stove with a big combustion chamber.

15. Charcoal stoves efficiency: The primary air supply to a charcoal fire can be reduced close to zero and the fuel will keep burning. Once the air supply is increased, the firepower will increase. Normally there is a spike in pollutants when the air supply is increased sharply, but it will stabilize once the firepower comes back up.

16. Fixing high heat and jets of secondary air to burn the Carbon Monoxide: Insulate the stove body to get higher temperatures in the combustion chamber and to lose less heat into the body of the stove. Put the pot close to the charcoal this will maximize heat transfer from radiation. Use a pot skirt with small channel gaps between the pot and stove. 8mm usually works well. This will maximize convective heat transfer. Maintain constant cross-section area throughout the stove. This will help to keep the velocity of the draft high assisting heat transfer efficiency.& Get more information about Bioenergy. Get your free ebook related to Bioenergy Potential.

17. The jet-flame reduces emissions and makes more efficient use of larger and even moist wood pieces. The jet flame also compatible with three stone fires and earthen stove for indoor Sustainability.

18. Obstruction of stove pollution: By increasing air exchange rates, chimneys, hay boxes, and improved combustion and heat transfer efficiency in stoves, etc. can decrease concentrations of PM 2.5 in kitchens. Certainly, combining the most applicable and locally effective interventions seems to make the most sense.

19. Exchange rate Vs Emissions rate in kitchen for indoor sustainability. The single zone box model was used to derive the WHO emissions rates targets that meet the WHO indoor air quality guidelines. The model predicts that at an air exchange rate of 15/hr and a cooking time of 4 hours an average emissions rate of 1.75 mg/min is needed to achieve an average indoor air concentration of 35 ug/m3 over a 24 hr period. Doubling the air exchange rate to 30/hr would allow an emissions rate of 3.5 mg/min.

20. WHO Recommendation for women in kitchen: It was confirmed that the WHO measured concentrations at a height of 1.6 m above the floor, but it was determined that it overpredicted the measured concentration by 23 to 63% at a height of 1.3 meters, and between 83 and 151% at a height of 1 meter. A height of 1.3 m can be associated with the breathing position of a standing woman of average stature, and a height of 1 m can be associated with her sitting position. Using the correction from the paper the health-protecting emissions rate at a height of 1.3 meters and an air exchange rate of 30/hr would be between 4.3 and 5.7 mg/min. At 1 meter the emissions rate could be between 6.4 and 8.7 mg/min.

Conclusions:

These are the few implications that can help in reducing indoor pollution. These all postulates are gathered from deep analysis of different newsletters, research journals, thesis or dissertation, and many resources. These 20 techniques also lead to the manure of new research topics. Finally, these all steps can make indoor Sustainability & obstruct the hazardous effects of smoke during Cooking. In short, these important steps lead to Indoor Sustainability development.

For related articles biofuelspk

You may find it helpful by following the links which give immense information & data regarding indoor sustainability